5 Essential Criteria for Choosing the Right Bolt

Bolts are fundamental components in construction, automotive, machinery, and various other industries. The quality and suitability of the bolts used in any structure or mechanical system are crucial for ensuring the overall safety and durability of the project. Incorrect bolt selection can lead to significant safety risks and costly failures. Therefore, it is essential to consider various criteria when choosing the right bolt. In this article, we will explore the five most important factors to consider when selecting bolts.

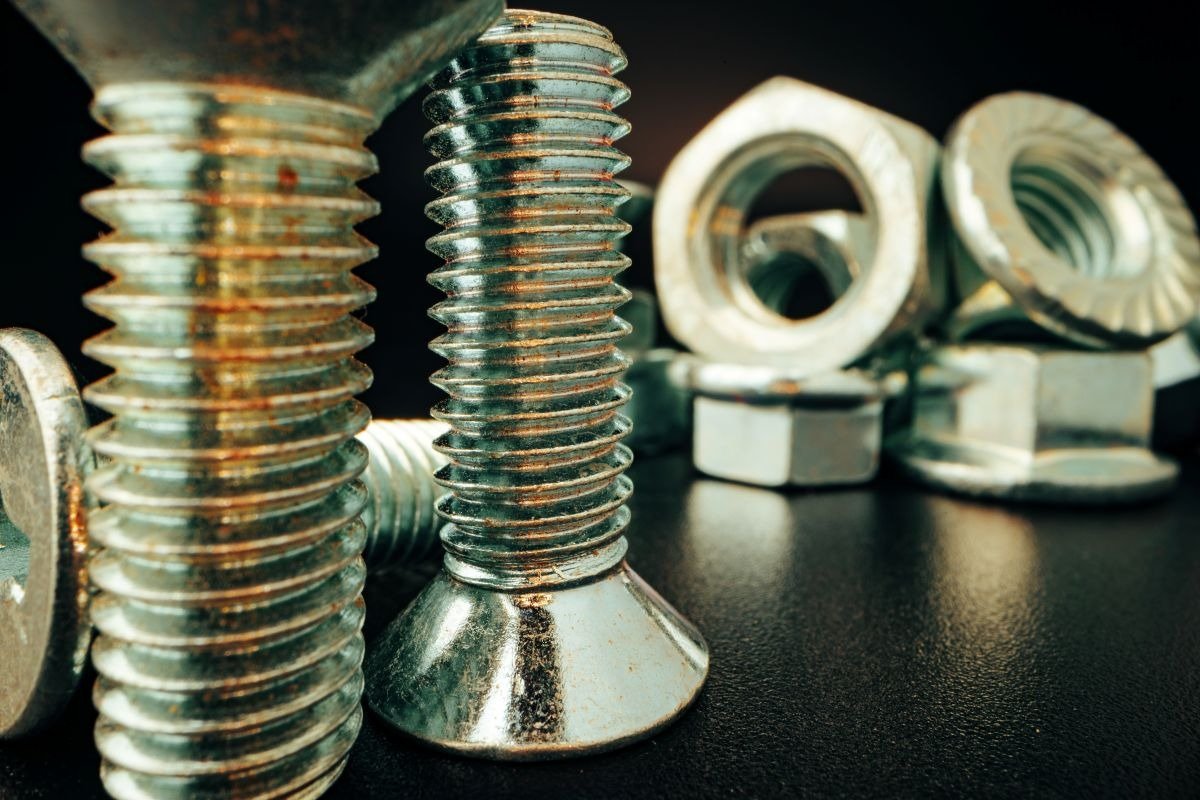

1. Material Type:

Bolts can be made from various materials, including steel, stainless steel, brass, bronze, and nylon. Each material has its unique advantages and applications. For instance, stainless steel bolts are highly resistant to corrosion, making them ideal for outdoor and marine applications. Steel bolts, on the other hand, are known for their strength and are commonly used in construction and mechanical engineering projects. Selecting the right material ensures that the bolt will be durable and reliable.

2. Strength Grade:

The strength grade of a bolt determines its load-bearing capacity and is usually marked on the bolt itself. Common strength grades include 4.6, 8.8, 10.9, and 12.9, indicating the tensile strength and yield strength of the bolt. For example, a grade 8.8 bolt is considered medium strength and is used in various general engineering applications. Choosing the appropriate strength grade for your project is essential for ensuring safety and performance.

3. Size and Length:

Selecting bolts of the correct size and length is crucial for the integrity of the connection. The diameter and length of the bolt must match the thickness of the materials being joined and the size of the holes. Using an incorrectly sized bolt can lead to weak connections or bolt failure. Therefore, it is vital to measure the application area accurately and choose bolts that fit perfectly.

4. Coating and Surface Treatment:

Bolts can be treated with various coatings to enhance their resistance to environmental factors. Zinc plating is a common surface treatment that increases corrosion resistance. Other treatments include galvanizing, nickel plating, and cadmium plating. The right coating can significantly extend the life of the bolt and improve its performance, especially in harsh environments. Choosing the appropriate surface treatment is crucial for applications exposed to moisture, chemicals, or extreme temperatures.

5. Application Area:

The specific application area of the bolts greatly influences the selection criteria. For indoor applications, standard steel bolts may suffice due to the lower risk of corrosion. However, for outdoor or underwater applications, bolts made from materials with high corrosion resistance, such as stainless steel, are necessary. Additionally, applications involving dynamic loads require bolts with higher strength grades. Understanding the environmental conditions and load requirements of the application area helps in selecting the most suitable bolts.

Choosing the right bolt is critical for the safety and durability of any project. By considering factors such as material type, strength grade, size and length, coating and surface treatment, and the application area, you can ensure that you select bolts that meet your project's specific needs. The correct choice not only reduces costs but also enhances safety and longevity. Remember, the right bolt is a cornerstone of a successful project.