New Materials and Alloys in Fasteners

Fasteners are fundamental components of industrial production and play a critical role in many sectors such as construction, automotive, aerospace, and electronics. While traditional materials like steel and stainless steel have been commonly used, advancements in technology and material science are revolutionizing the fastener industry with new materials and alloys. These innovative materials offer significant advantages in areas like performance, durability, weight reduction, and corrosion resistance.

In recent years, the importance of light yet strong materials has increased. Especially in the aerospace and automotive industries, reducing the weight of vehicles to improve fuel efficiency and lower carbon emissions has become a critical goal. In this context, lightweight metals such as titanium and aluminum alloys have started to be used more frequently in fasteners. Titanium, with its high strength and low density, is preferred in applications requiring high performance, such as aircraft and racing cars. Additionally, its excellent corrosion resistance makes it suitable for marine applications.

Aluminum and its alloys are popular in the automotive and construction industries due to their low weight and good mechanical properties. Aluminum fasteners offer sufficient strength while being one-third the weight of steel. Furthermore, the recyclability of aluminum is a significant advantage in terms of environmental sustainability.

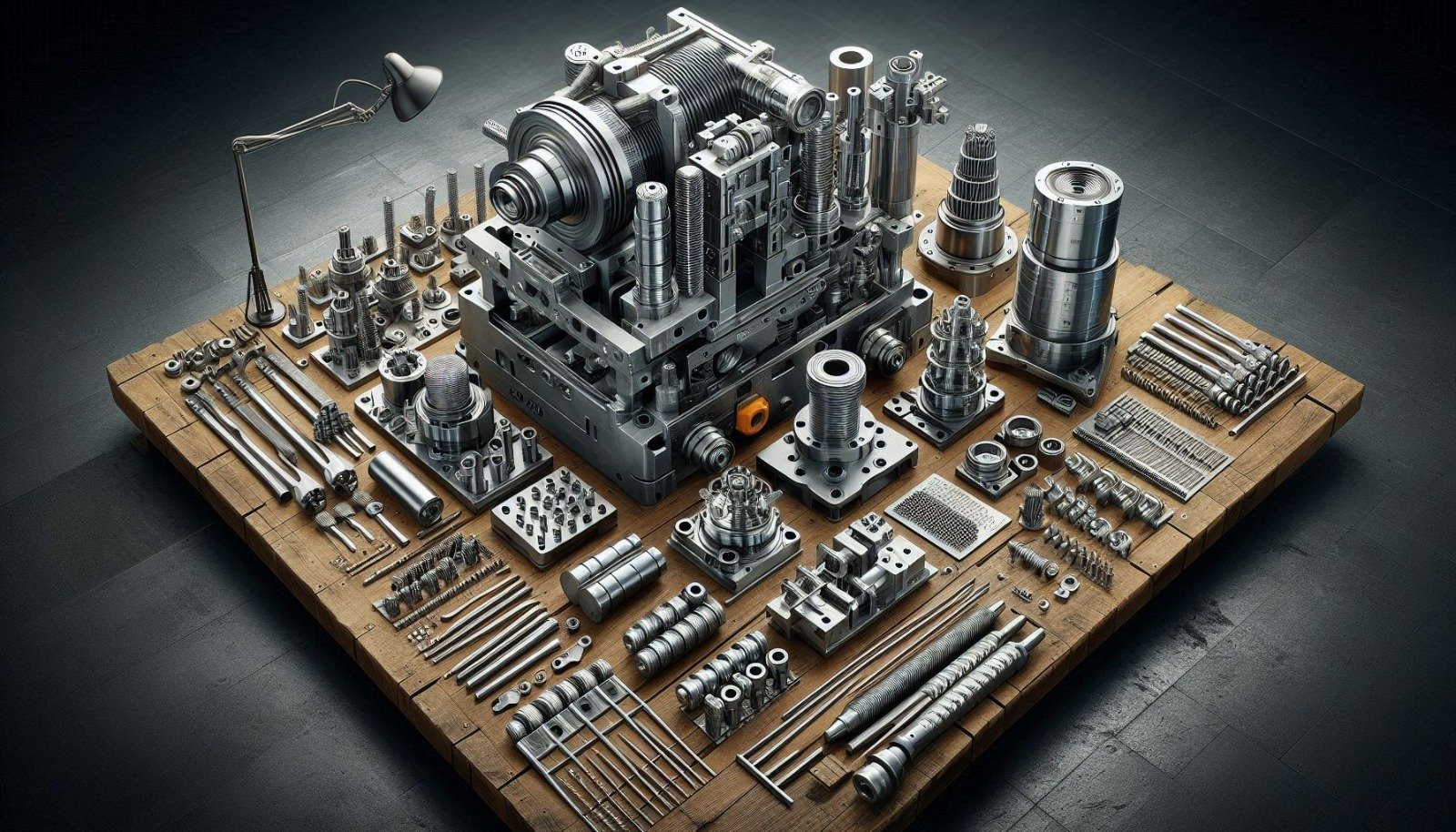

Composite materials are another innovative solution used in fasteners. Carbon fiber reinforced polymers (CFRP) provide high strength and stiffness while keeping weight to a minimum. These materials are increasingly used not only in the aerospace and space industries but also in sports equipment and the automotive sector. However, compatibility with metal fasteners and assembly techniques of composite materials require special attention.

Superalloys are materials that can withstand high temperatures and corrosive environments. Nickel-based superalloys are ideal for fasteners used in industries like power generation and chemical processing. These alloys maintain their strength at high temperatures and are resistant to oxidation.

Smart materials are emerging as a new trend in the fastener industry. Shape memory alloys contain metals that can return to their original shape at a specific temperature. This feature allows automatic correction of deformations that may occur during or after assembly. They have potential uses especially in precision mechanical systems and medical devices.

Innovations continue in stainless steel alloys as well. In addition to traditional stainless steels, duplex stainless steels offering higher corrosion resistance and mechanical properties are being developed. These materials extend the lifespan of fasteners in harsh environments like the oil and gas industry.

Nanomaterials and coatings are used to improve the surface properties of fasteners. Through nanotechnology, corrosion resistance, friction coefficient, and wear resistance can be enhanced. This significantly improves the performance and lifespan of fasteners.

The use of these new materials also brings some changes in the manufacturing processes of fasteners. For example, machining titanium and superalloys is more challenging compared to steel and requires specialized equipment. Therefore, manufacturers need to invest in technology and expertise to work with these materials.

Moreover, the cost of new materials must be considered. Materials like titanium and superalloys are more expensive than traditional steels. However, in the long term, the performance advantages they provide and the reduction in maintenance costs can justify this investment.

In conclusion, new materials and alloys in fasteners are evolving to meet the needs of the industry. Features such as lightness, high strength, corrosion resistance, and special functionalities are reasons for preferring these materials. It is important for businesses to closely follow these innovations and integrate them into their manufacturing processes to remain competitive and meet customer demands.