What is a Nut?

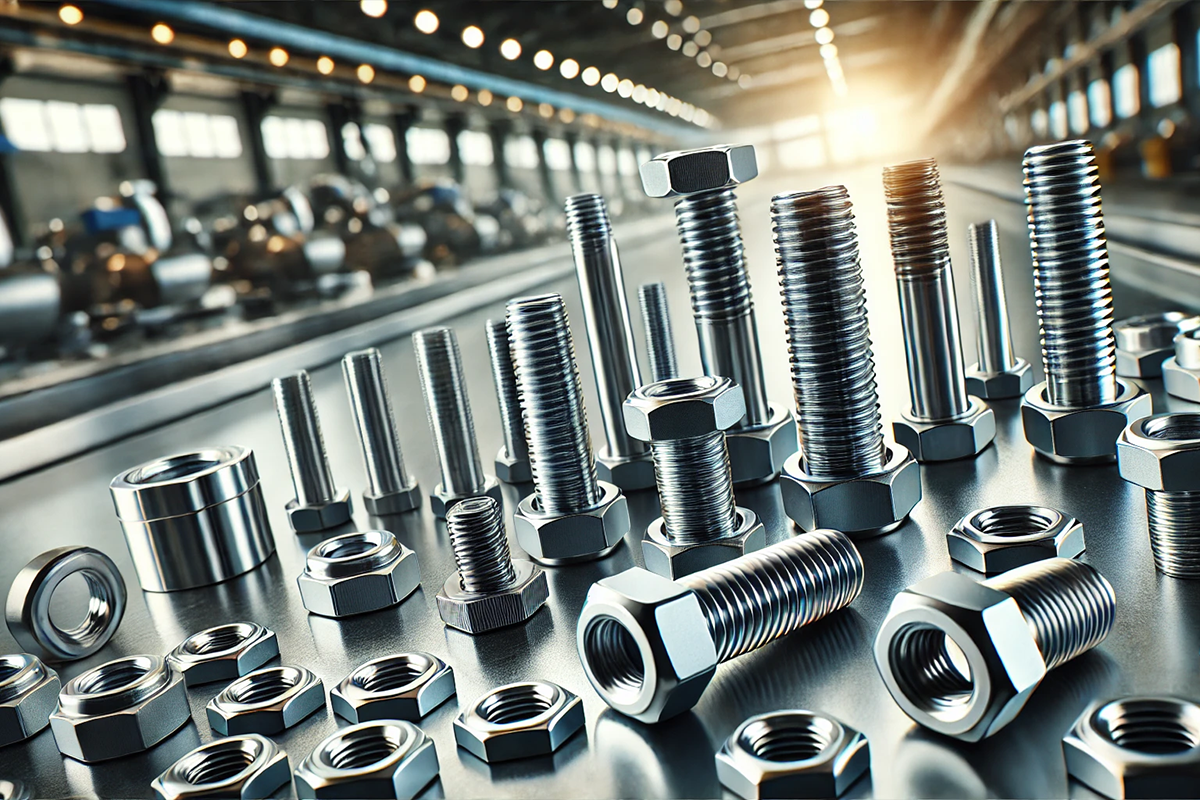

Today, fasteners used in the assembly of many structures, machines, and tools play a critical role in terms of durability and safety. One of the most commonly used fasteners is the nut. Nuts, when used with bolts, provide a strong and secure grip. So, what exactly is a nut, and where are they used? In this article, we will explore what nuts are, their types, and their areas of application.

One of the most important features of nuts is that they are produced in various sizes and types, making them suitable for a wide range of applications. The type of nut to be used in a project is chosen based on the conditions of the environment, the intended purpose, and the characteristics of the parts to be connected.

Types of Nuts

Nuts come in different designs to meet a variety of needs. Here are some of the most common types of nuts:

Definition of a Nut and Its General Features

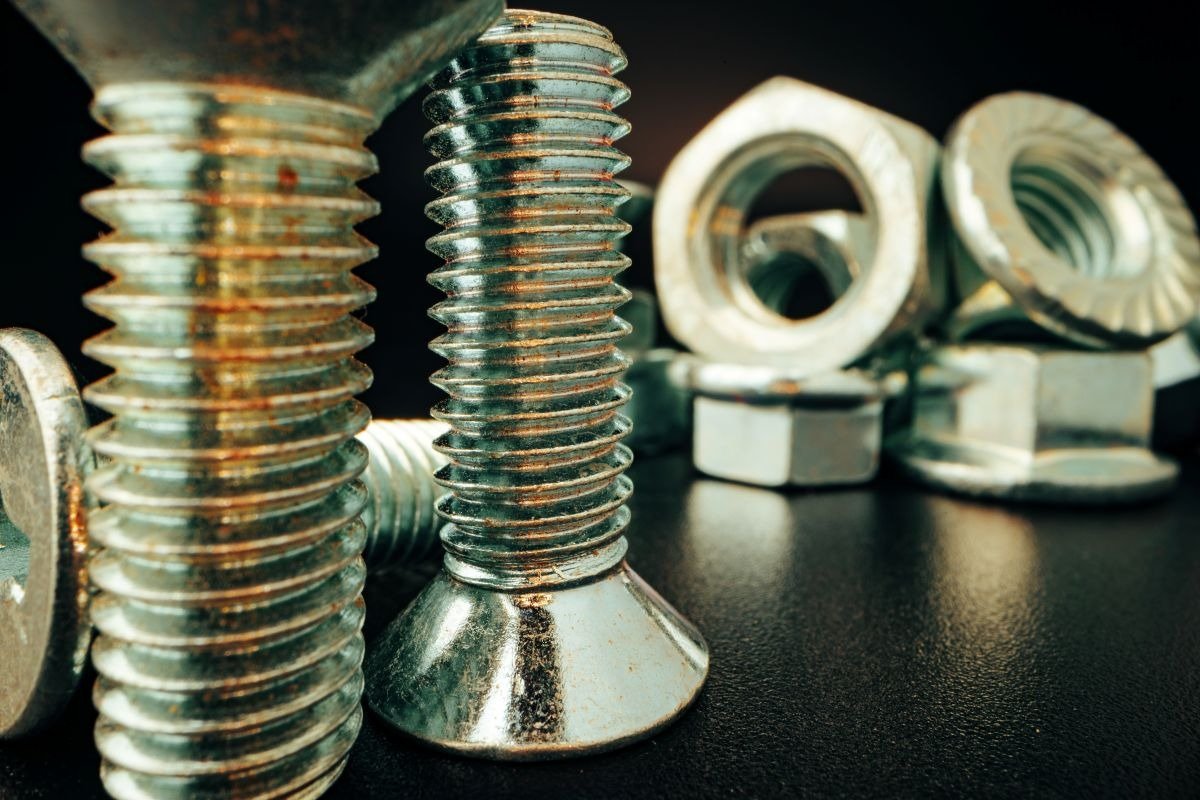

Nuts are fasteners, usually made of metal, that are attached to the ends of bolts. Their primary purpose is to secure a strong connection between parts when used with bolts. Nuts are easily mounted onto bolts thanks to their internal threaded structure, creating a firm bond. These fasteners are typically made from high-strength metals, but in some cases, plastic or composite materials may also be used to manufacture nuts.

Nuts are fasteners, usually made of metal, that are attached to the ends of bolts. Their primary purpose is to secure a strong connection between parts when used with bolts. Nuts are easily mounted onto bolts thanks to their internal threaded structure, creating a firm bond. These fasteners are typically made from high-strength metals, but in some cases, plastic or composite materials may also be used to manufacture nuts.

One of the most important features of nuts is that they are produced in various sizes and types, making them suitable for a wide range of applications. The type of nut to be used in a project is chosen based on the conditions of the environment, the intended purpose, and the characteristics of the parts to be connected.

Types of Nuts

Nuts come in different designs to meet a variety of needs. Here are some of the most common types of nuts:

- Hex Nuts: Hexagonal in shape, these nuts are one of the most widely used types. They are suitable for standard fastening operations and are usually tightened using wrenches. Their six-sided design prevents slippage, even under high torque.

- Flange Nuts: Flange nuts have a flange, or a wide base, at the bottom. This flange increases the contact area with the surface below the nut, reducing the risk of loosening. They are commonly used in environments with vibrations.

- Lock Nuts: Lock nuts provide a more secure connection compared to standard nuts because they do not loosen on their own. They are typically used in applications where there is a risk of loosening due to vibrations or impacts. Lock nuts may contain plastic, metal, or spring mechanisms to increase security.

- Wing Nuts: Wing nuts can be easily tightened by hand. The wing-like protrusions on the nut allow for manual tightening without the need for tools. They are often preferred for quick and temporary connections.

- Square Nuts: Square nuts, which are four-sided, are typically used for simple structures and applications requiring low torque. Their square shape allows for better surface contact, but they are not as common as hex nuts.

Applications of Nuts

Nuts are widely used across various industries and fields. Here are some of the most common sectors where nuts are found:

Nuts are widely used across various industries and fields. Here are some of the most common sectors where nuts are found:

- Construction and Building Industry: Nuts used in building construction, scaffolding, and other structures help ensure the strength and durability of buildings. They are frequently used in steel structures.

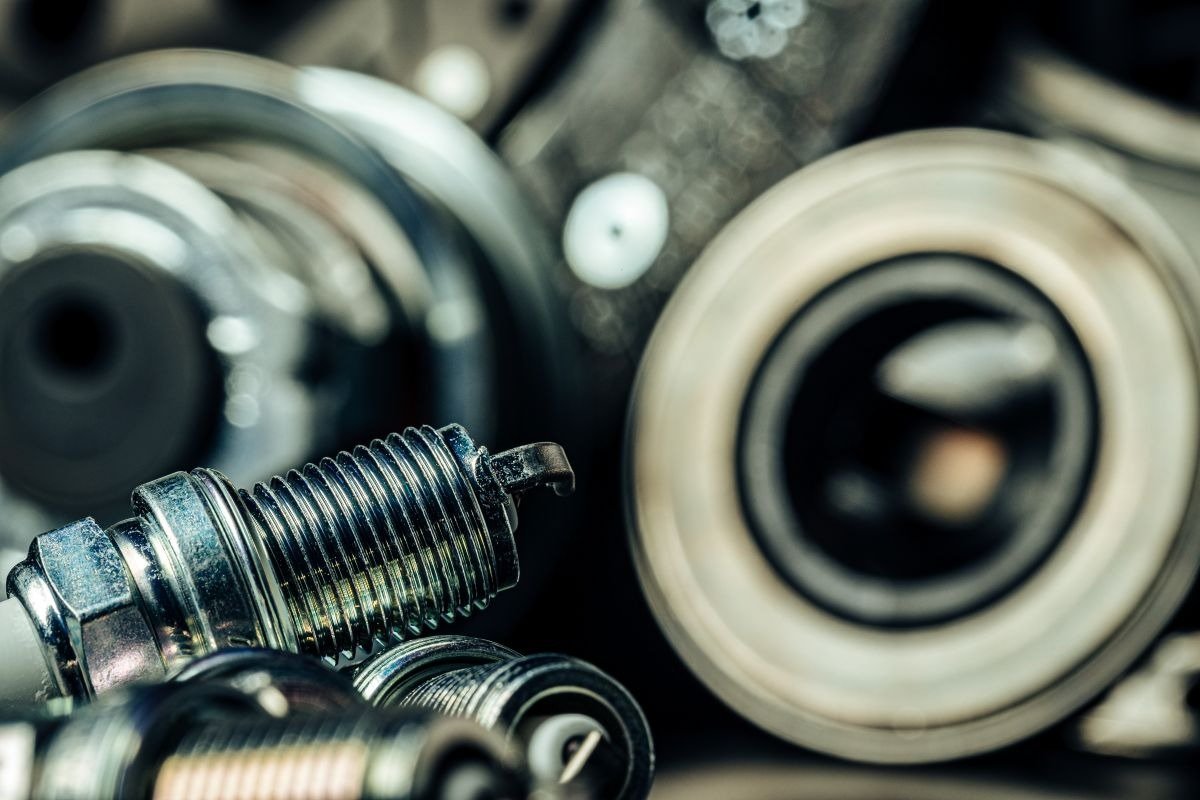

- Automotive Industry: Nuts are essential in the assembly of vehicles, playing a crucial role in securing engine parts and other components. Lock nuts are often used in vibrating environments to enhance safety.

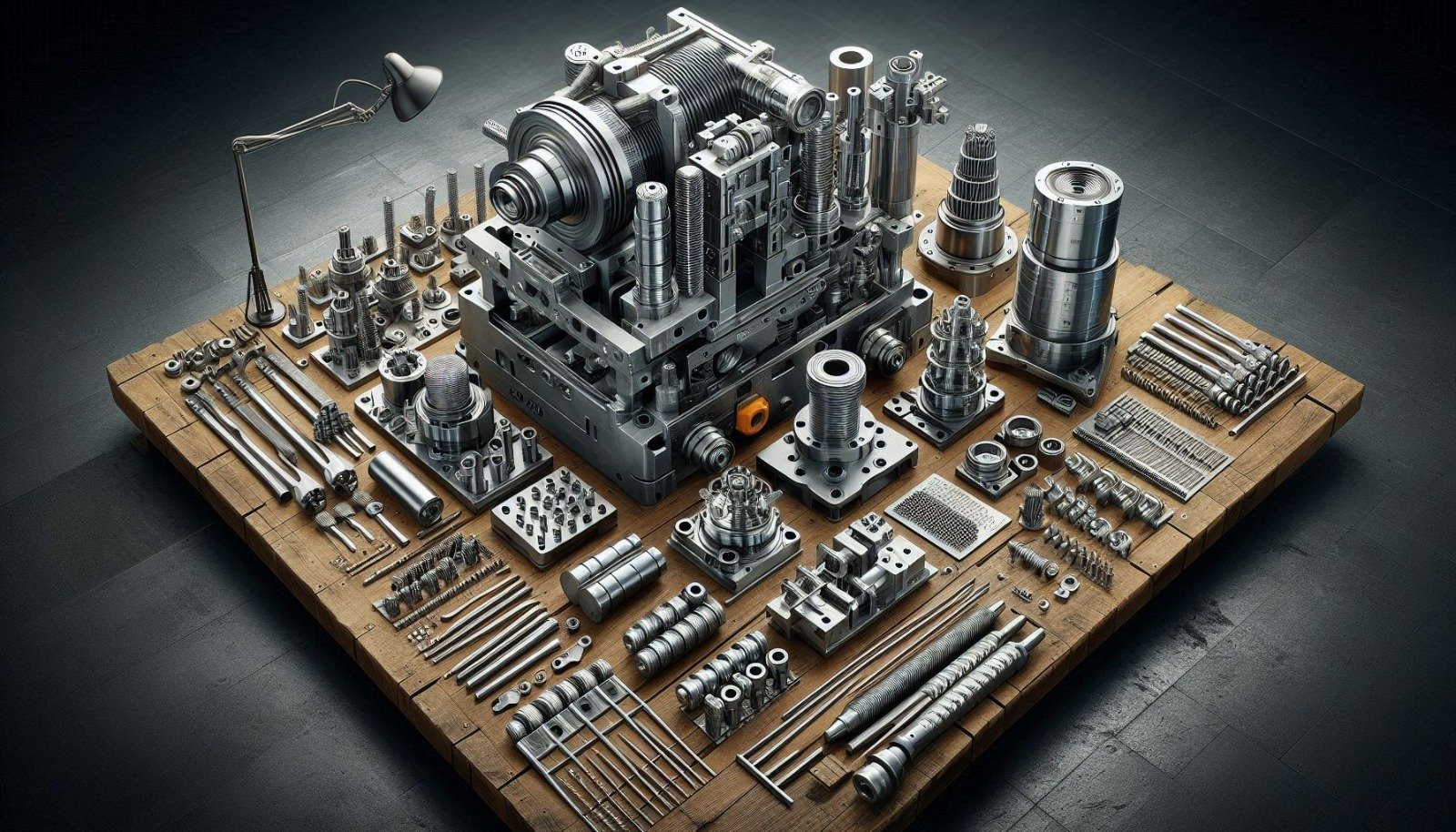

- Machinery Manufacturing: Nuts are widely used in the production, assembly, and maintenance of machines. Choosing the right nuts during the assembly of machine parts ensures long-lasting and safe operation.

- Furniture Industry: Nuts are also commonly used in furniture assembly. Wing nuts, in particular, allow users to assemble furniture easily without requiring any tools.

Nut Selection

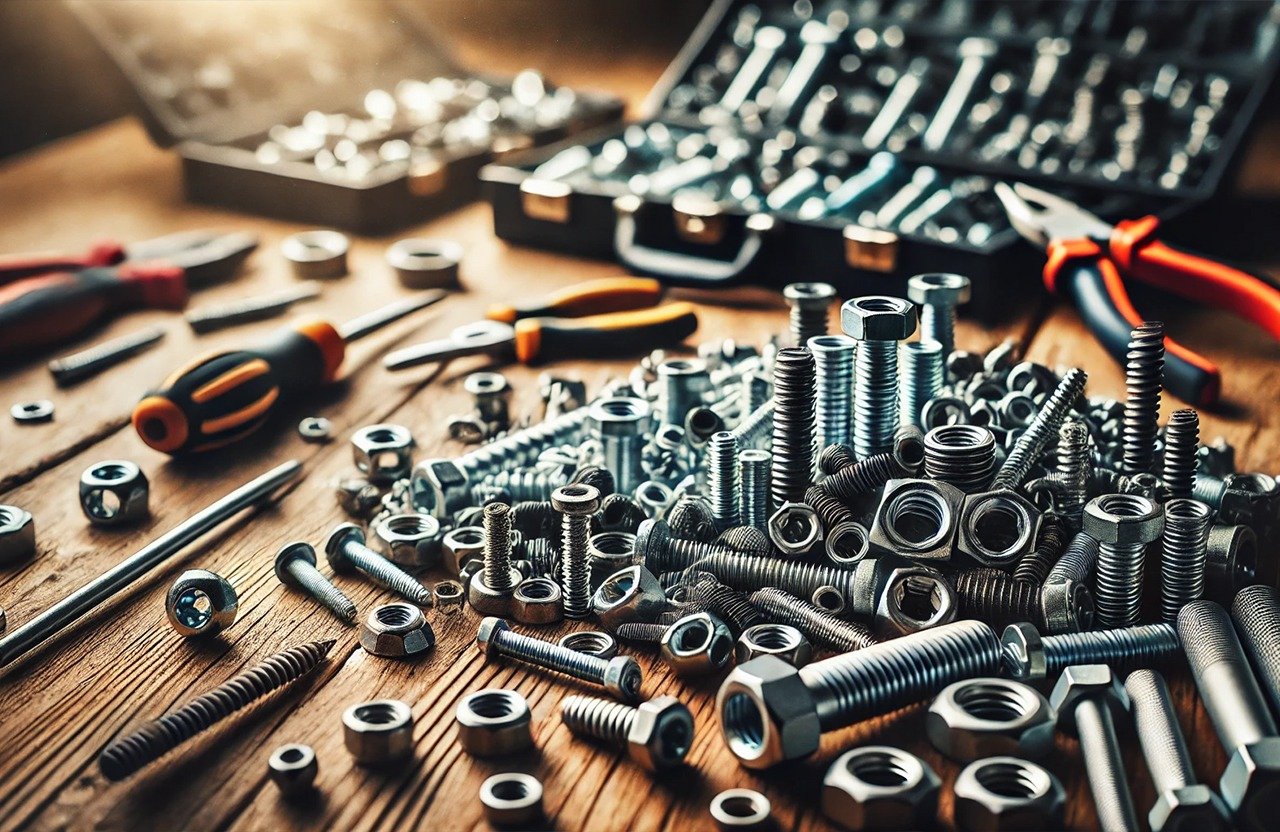

Choosing the right nut is essential, depending on the project. Incorrectly selected nuts can lead to weak connections and pose safety risks. Key factors to consider when selecting nuts include:

Choosing the right nut is essential, depending on the project. Incorrectly selected nuts can lead to weak connections and pose safety risks. Key factors to consider when selecting nuts include:

- Material: The material of the nut should be suitable for the environment. Stainless steel nuts are preferred in humid and outdoor conditions, while plastic nuts can be used for lighter applications.

- Size: The diameter of the nut must match the bolt. An improperly sized nut can compromise the security of the connection.

- Lock Mechanism: If there is a risk of the nut loosening, lock nuts should be preferred for added security.

Nuts play a critical role in various sectors, from construction to automotive, machinery manufacturing to furniture assembly. The type, material, and size of the nut are essential for ensuring the safety and durability of a given project. By carefully selecting the right nut for the job, long-lasting and secure results can be achieved. Therefore, it is important to choose the appropriate nut for each project, considering its purpose and the conditions it will be exposed to.