Where Are Special Bolts and Nuts Used?

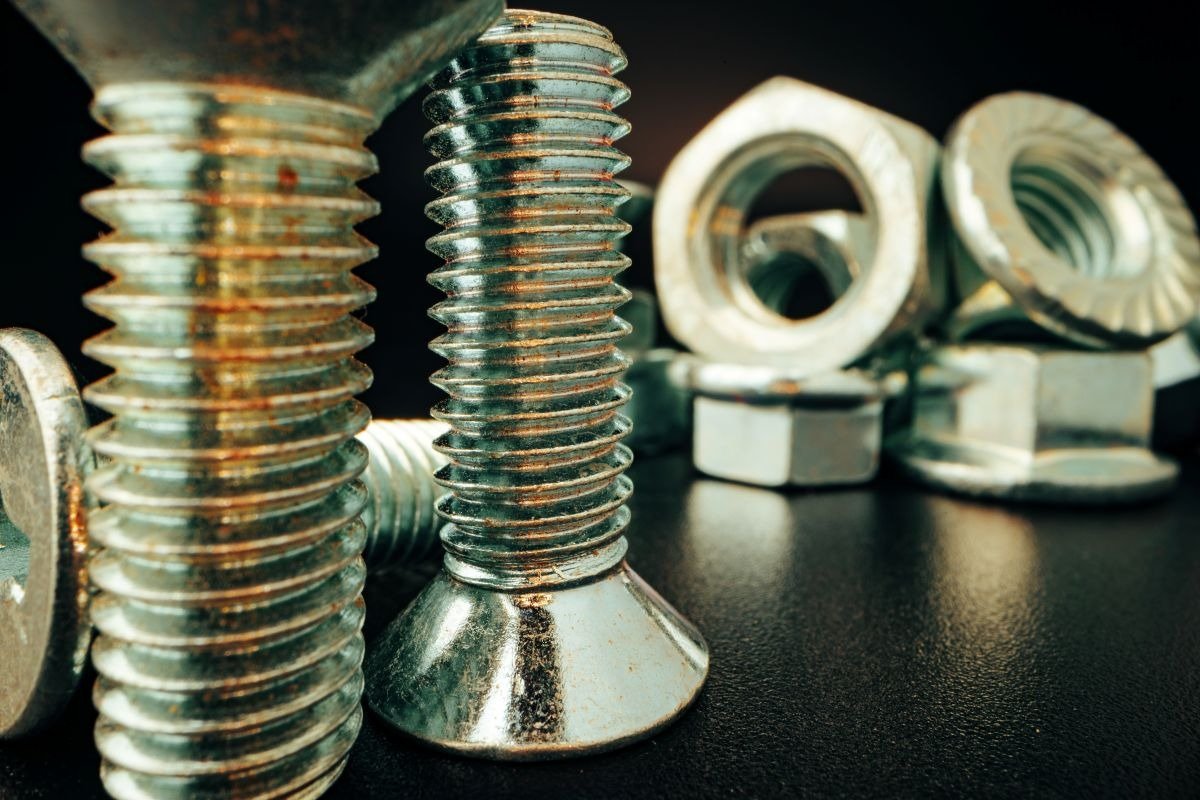

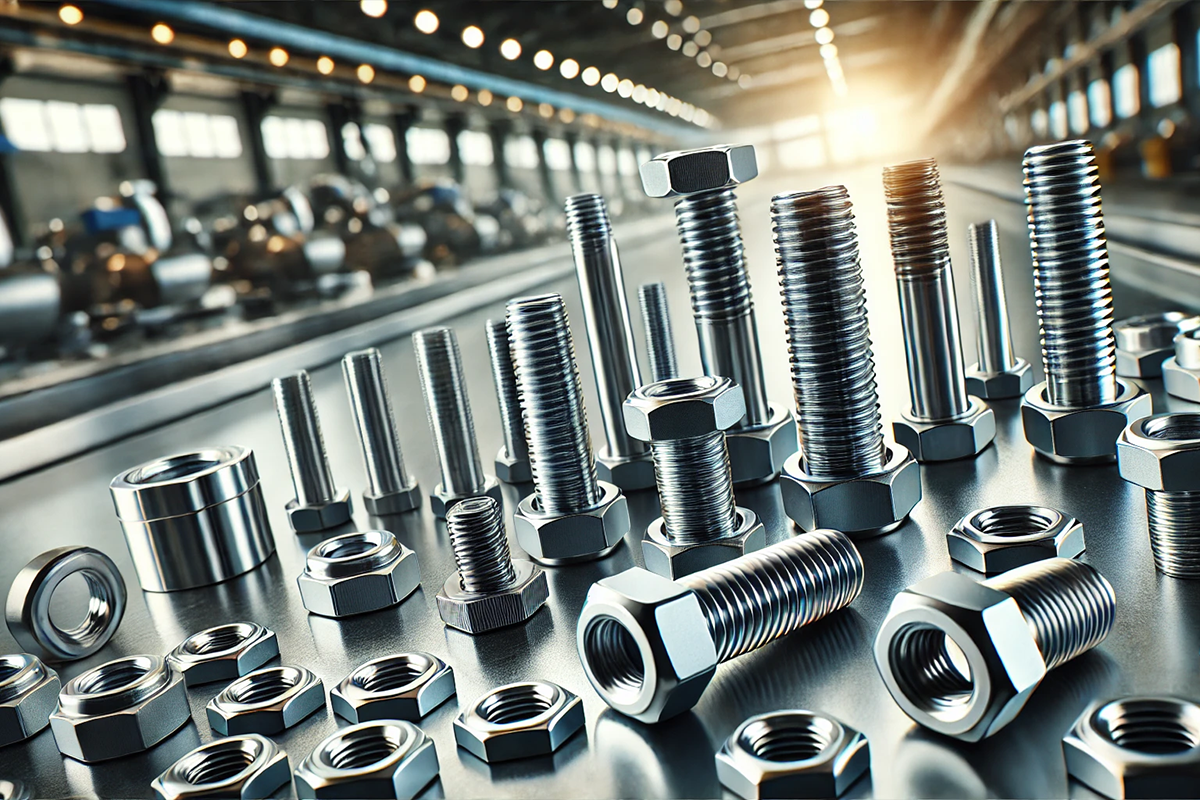

Special bolts and nuts play a vital role in various industrial and construction applications. These components offer more than standard structural elements, designed to meet specific design and functional requirements.

In the construction sector, special bolts and nuts are used at critical points requiring structural strength. For instance, they are specially designed to ensure reliability at the fundamental connection points of bridges and buildings. Durability and longevity are essential in these applications, which is why steel and alloy materials are used.

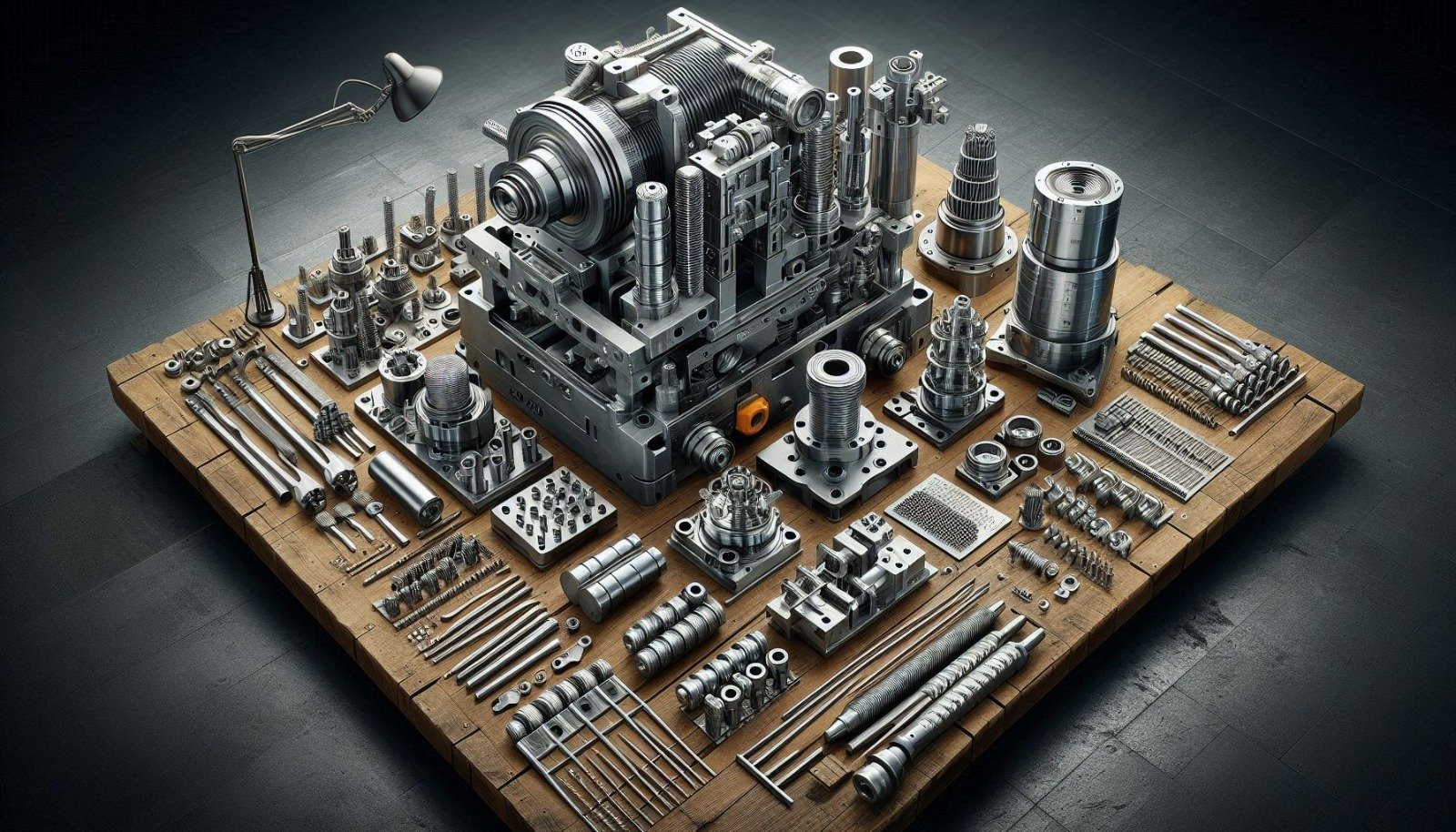

In mechanical engineering and industrial equipment production, special bolts and nuts are crucial for holding machine parts together and ensuring proper alignment between moving components. These parts are typically made from high-strength steels and can be designed to meet specific vibration prevention or load-bearing requirements.

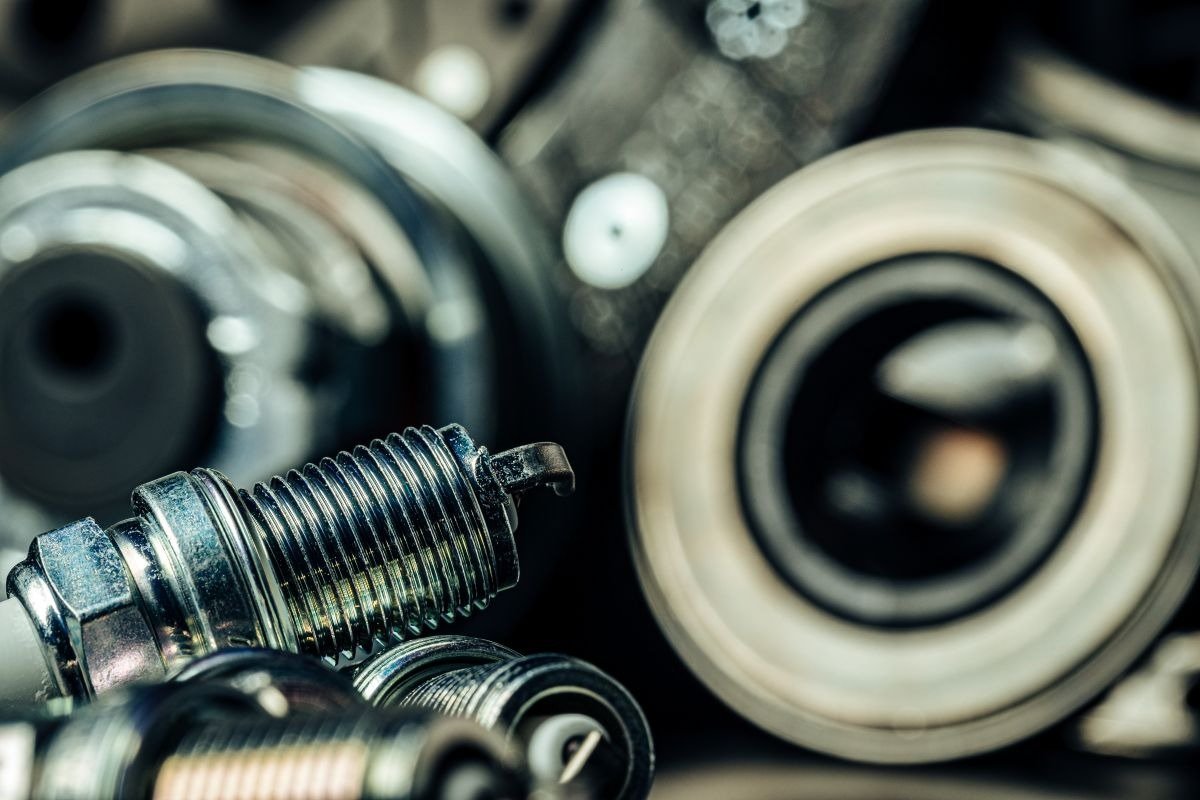

In the automotive industry, special bolts and nuts play a vital role in vehicle safety and performance. They are used in a wide range of applications, from engine assembly to suspension systems. Here, special parts made from lightweight materials and designed for durability come to the fore.

Energy production and transmission are among the critical application areas for special bolts and nuts. In this sector, special designs are required to ensure the reliability and durability of large structures such as wind turbines, hydroelectric plants, and electric poles. Bolts and nuts coated with special coatings or made from corrosion-resistant materials are preferred for use in high-voltage environments.

Special bolts and nuts are fundamental components in various industrial and construction applications. They are specially designed to meet different functional requirements in each sector and are critical for providing high durability, safety, and performance.

The Secret of Industrial Giants: Application Areas of Special Bolts and Nuts

One of the secrets of success in industry is meticulous attention to every detail and the use of specially designed parts. Special bolts and nuts are particularly critical in many industrial applications. These special parts are designed to enhance the reliability and performance of machines.

Special design bolts and nuts can be manufactured according to the requirements of each application. These parts, made from different materials, generally offer high durability and long service life. For instance, these parts used in heavy industry machinery perform optimally in environments requiring continuous vibration and high strength.

Durability and Safety: The Use of Special Bolts and Nuts in Industry

Industrial giants place great importance on special bolts and nuts for the safety and durability of their products. These parts provide a solid connection during assembly, ensuring that products operate smoothly for a long time. Additionally, they provide stability and safety even in systems operating under high pressure and extreme temperatures.

Application Variety: Use of Special Bolts and Nuts in Different Industries

Special bolts and nuts are used in a wide range of applications, from the automotive industry to shipbuilding, from aviation to the energy sector. Each industry can use these parts designed according to its specific requirements to improve the quality and performance of its products.

Special bolts and nuts form one of the secrets of the success of industrial giants. These parts enhance the efficiency and reliability of industrial machinery and systems by providing perfect fit, durability, safety, and wide application variety. Bolts and nuts designed specifically for the needs of each sector will continue to play a critical role in the future of the industry.