Bolt Types Used in the Construction Industry and Their Features

The construction industry is a field that requires

meticulous selection down to the smallest fasteners to ensure the safety and

longevity of structures. At this point, bolt types play a critical role

in ensuring structural integrity. From steel structures to reinforced concrete

systems, from roof connections to prefabricated buildings, different bolt

types are used at every stage.

What Are the Bolt Types Used in the Construction Industry?

We can summarize the bolt types used in the construction

industry and the features that make them stand out as follows:

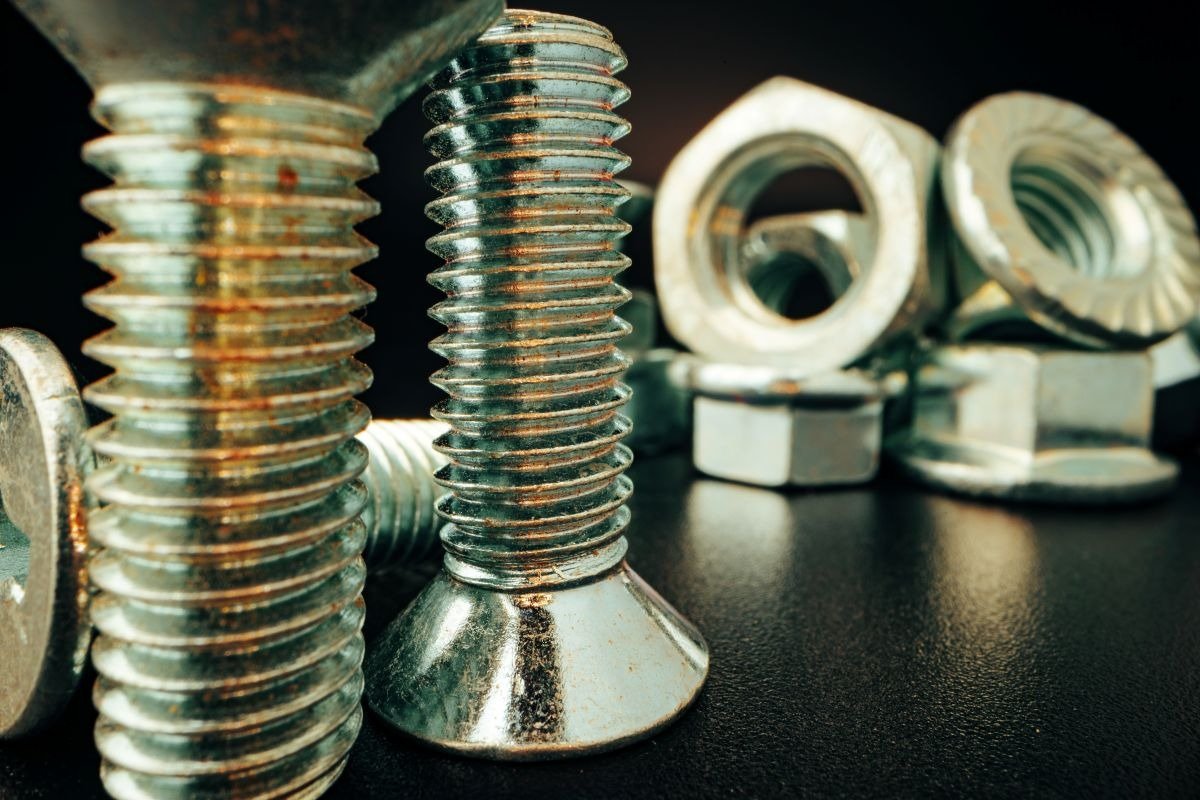

Metric Bolts

Metric bolt types are among the most commonly used

fasteners in the construction sector. Known for their standard sizes and

millimetric thread designs, these bolts are especially preferred in steel

construction systems. Manufactured in accordance with DIN and ISO standards, metric

bolt types are classified based on their tensile strength classes (such as

8.8, 10.9, 12.9), corresponding to different load-bearing capacities. For

example, using bolts with a 10.9 strength grade in a bridge project is crucial

for resistance against dynamic loads.

High-Strength Bolts

In construction projects involving heavy loads—such as

bridges, cranes, and industrial facilities—high-strength bolts are used. These

bolts offer greater tensile resistance compared to regular bolts and are

usually made of heat-treated steel. They are protected against corrosion with

special coatings (e.g., hot-dip galvanization). Among bolt types and usage

areas high-strength bolts are among the most critical, as they can perform

without deformation even under sudden impact loads.

Anchor Bolts

In reinforced concrete structures, anchor bolts are used to

secure steel elements to concrete. These bolts are embedded into the concrete,

essentially integrating with the structure. They can be manufactured with

straight ends or bent in L or J shapes. Especially in column base connections,

machine footings, and industrial floors, anchor bolts are indispensable among special

bolt types. When used with epoxy or chemical anchoring systems, they

provide highly reliable connections against tensile and shear forces.

Stainless Steel Bolts

In humid and aggressive environments such as seaside

structures, pool areas, or chemical plants, stainless steel bolts are

preferred. Produced in AISI 304 or AISI 316 grades, these bolts are known for

their resistance to oxidation. In glass façade systems or decorative metal

works—where aesthetics also matter—stainless steel bolts stand out among bolt

types names, offering both visual and technical satisfaction.

Custom-Designed Bolts

Some construction projects may require technical

specifications that standard bolts cannot meet. In such cases, special bolt

types come into play. Examples include titanium alloy bolts for

long-lasting structures, heat-resistant bolts for high-temperature

environments, or seismically enhanced bolts for earthquake zones. Bolt types

and usage areas can be customized according to project-specific needs.

Special bolts are manufactured based on engineering calculations and are

optimized in terms of size, thread structure, or material to meet project

demands.

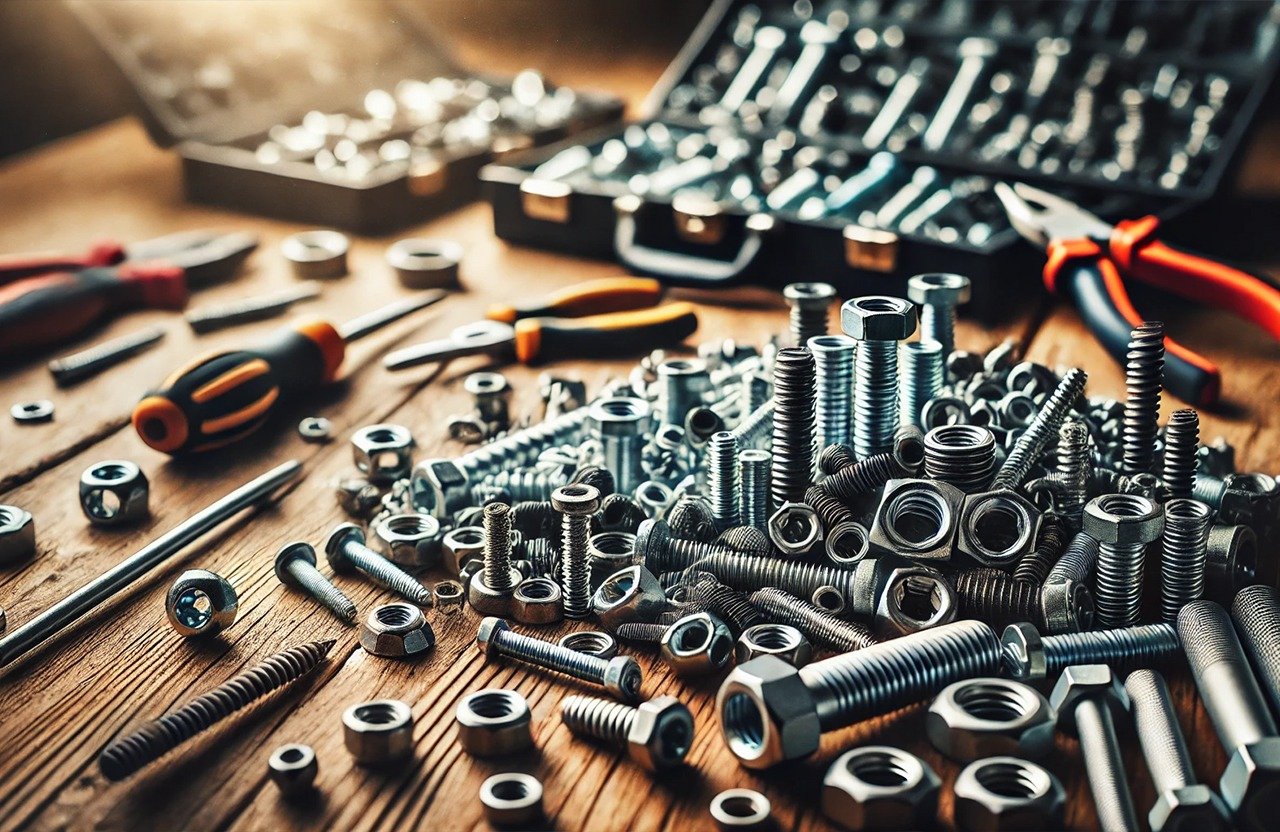

How to Choose the Right Bolt?

The most important factors to consider when selecting bolt

types for a construction project are environmental conditions, the type of

load to be carried, and the structure’s lifespan. Choosing the wrong bolt can

lead to loosening, corrosion, or sudden breakage over time. Therefore, during

the technical purchasing process, the focus should be not only on price but

also on quality and suitability.

In conclusion, the bolt types used in the construction

industry and their characteristics are an indispensable part of building

safety. Choosing the right fasteners is one of the most critical engineering

decisions to ensure a building's durability. Our company supports every stage

of your construction projects with a wide range of bolt types names and

technical expertise in industrial product supply.