Precision Fastener Technologies in the Aerospace and Aviation Industry

In the aerospace and aviation industries, increasingly complex and specialized systems are being developed every day. One of the most important components in these sectors is precision fasteners. In this article, we will delve into the technologies of precision fasteners used in the aerospace and aviation industries.

Precision Fasteners and Their Key Features

Precision Fasteners and Their Key Features

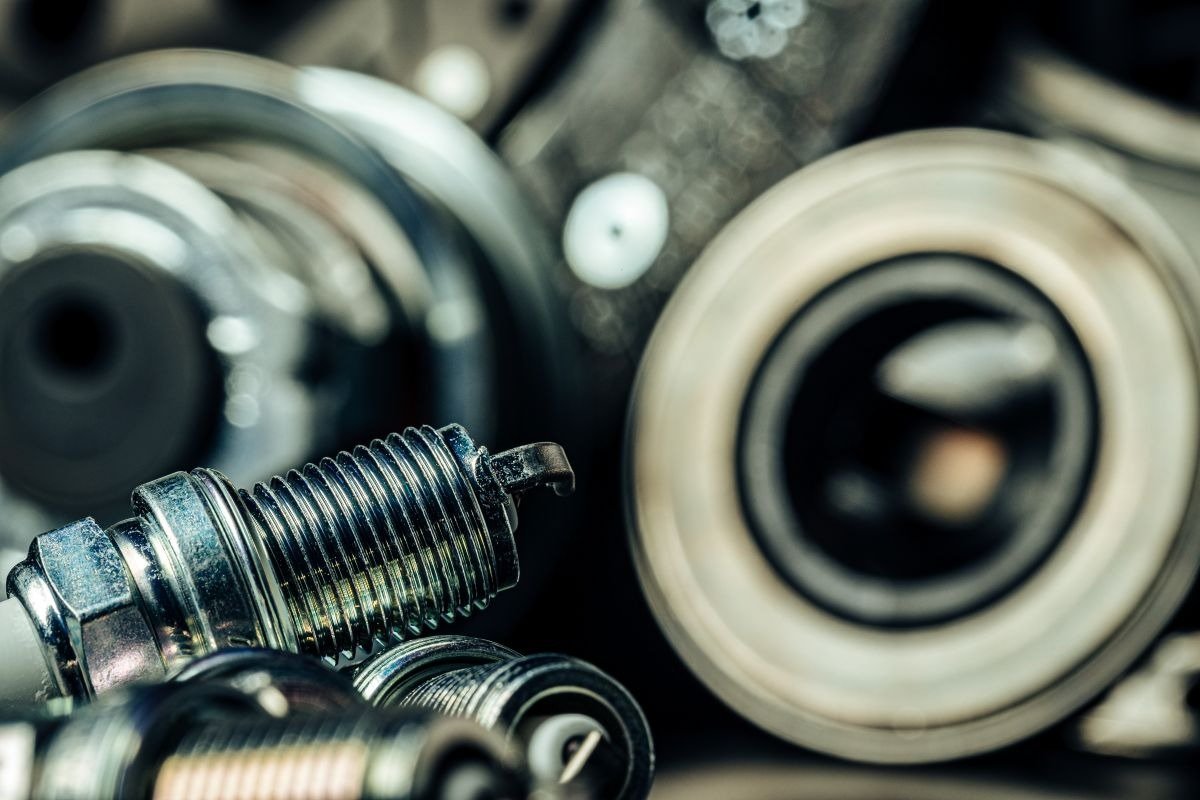

Precision fasteners are critical elements that influence the durability, safety, and performance of the vehicles and systems used in the aerospace and aviation industries. These fasteners are typically made from special materials such as lightweight metals, titanium alloys, and special polymers. Their key characteristics include high strength, low weight, and durability.

Special Designs for Spacecraft

Special Designs for Spacecraft

Spacecraft are exposed to extreme conditions outside the Earth, so their fasteners must deliver special performance. Fasteners developed for spacecraft are designed to withstand extreme temperature changes, radiation, and vacuum environments. Carbon fiber-reinforced composite materials and alloys optimized for use in space are utilized to enhance the reliability of spacecraft. As space exploration and research continue to push boundaries, the role of precision fasteners in spacecraft design remains critical.

- Special Materials and Durability: Spacecraft require fasteners that are durable and long-lasting due to the harsh conditions they face. Special alloys, carbon fiber-reinforced composite materials, and titanium—lightweight and durable materials—are key components used to maintain the structural integrity of spacecraft.

- Resistance to Extreme Temperature Changes: Spacecraft are exposed to both extremely hot and cold temperatures outside the atmosphere. Fasteners in these conditions are equipped with special coatings and insulation to withstand these temperature fluctuations, ensuring that the spacecraft’s systems operate reliably even during long-term missions.

- Radiation Resistance: Solar radiation and other radiative effects in space have a significant impact on spacecraft. As a result, fasteners are often protected with radiation-resistant coatings. These coatings help safeguard electronic systems and sensitive equipment during prolonged exposure to space environments.

- Suitability for Vacuum Conditions: Space is characterized by a vacuum, requiring the specialized design of fasteners. Vacuum-compatible seals, sealing materials, and lubrication systems ensure that fasteners perform smoothly throughout the spacecraft's operational life.

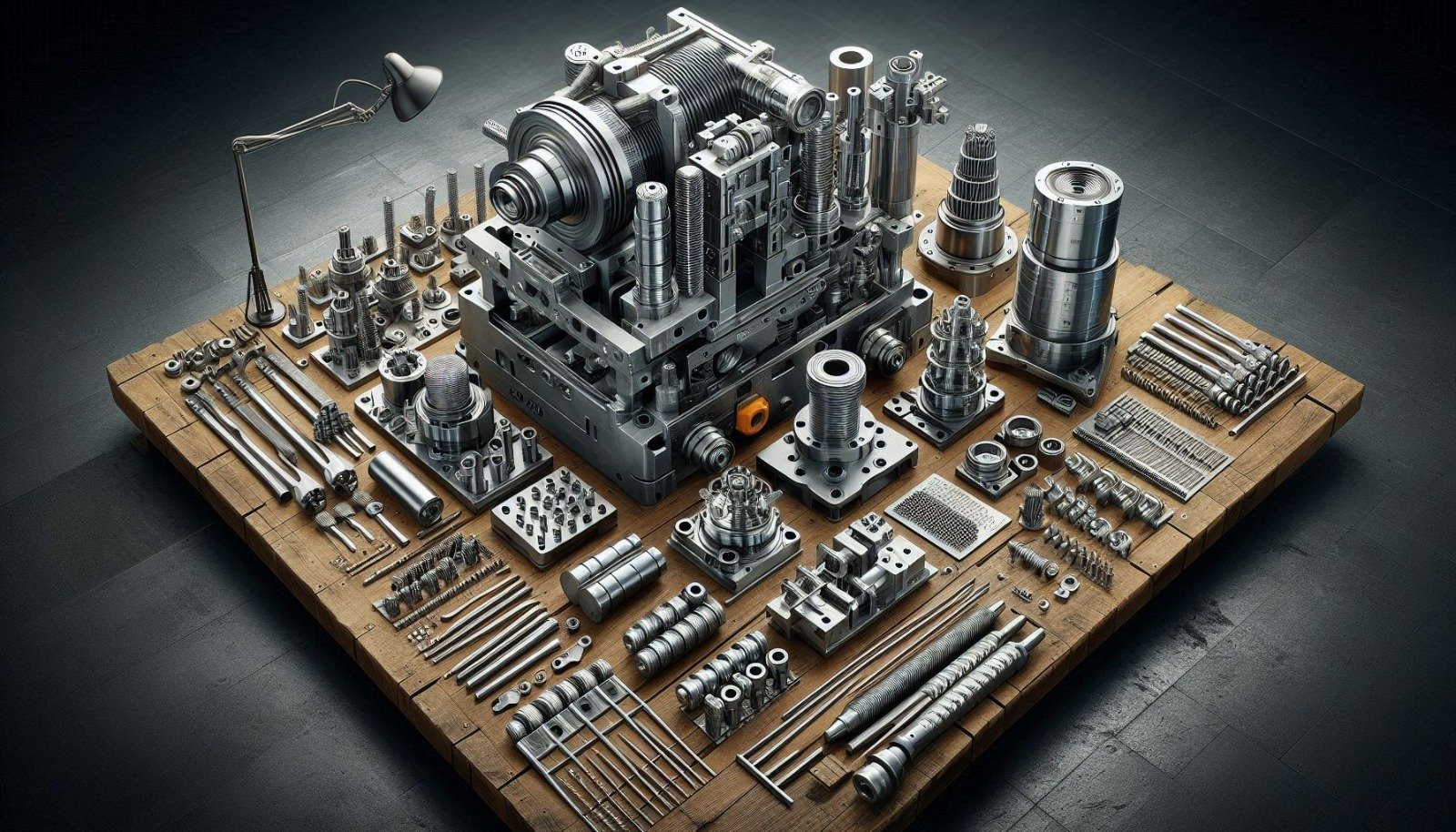

Special Design and Assembly Methods

When designing fasteners for spacecraft, specialized assembly and fastening methods are used. Precision robotic systems ensure that these fasteners are securely integrated with the spacecraft's components. The development of fasteners for space is crucial to the success of long-term missions, and as technology and material science advance, spacecraft fasteners continue to become more durable, lightweight, and efficient.

Advanced Technologies for Aviation Safety

The aviation industry must adhere to the highest safety standards. Precision fasteners play a critical role in aircraft safety, offering high strength and reliable connections. These fasteners are designed to withstand vibrations, wear, and extreme conditions experienced in flight. Special alloys and composite materials are used to maintain the lightweight nature of aircraft.

Future Developments and Innovations

The aviation industry must adhere to the highest safety standards. Precision fasteners play a critical role in aircraft safety, offering high strength and reliable connections. These fasteners are designed to withstand vibrations, wear, and extreme conditions experienced in flight. Special alloys and composite materials are used to maintain the lightweight nature of aircraft.

Future Developments and Innovations

Ongoing advancements in precision fastener technologies are set to propel the aerospace and aviation industries even further. Innovative methods such as 3D printing, nanotechnology, and artificial intelligence will allow for the production of lighter, more durable fasteners. These developments can improve efficiency within the sector and enable new discoveries in space exploration.