Bolt Tightening Techniques: How to Perform the Process Correctly?

The strength of a structure depends not only on the quality

of materials used but also on the correct techniques applied during the

assembly process. Especially when it comes to bolt installation, what may seem

like a simple task is actually a delicate and detail-oriented procedure. Bold

tightening techniques play a crucial role in ensuring the safety and

longevity of a structure. A bolt that isn’t tightened to the proper torque

value may loosen over time, compromising both performance and safety.

How to Tighten a Bolt?

How to tighten a bolt? The answer involves much more

than just applying force. Appropriate tools must be used during the process,

torque values should be adjusted in line with manufacturer standards, and the

tightening method must be carefully selected. Particularly in professional

settings, the process should follow a specific sequence rather than being done

randomly. For example, tightening two opposing bolts alternately and with equal

force helps ensure the surface sits evenly. This method is known as

cross-tightening and is essential for balanced load distribution.

Where to Tighten a Bolt?

Another frequently asked question is: Where to tighten a

bolt? Generally, bolts are tightened clockwise, meaning to the right. This

is the standard for nearly all threaded bolts. However, in special

applications, reverse-threaded (left-hand thread) bolts may be used. Therefore,

it’s important to check the type of thread before determining the direction of

tightening.

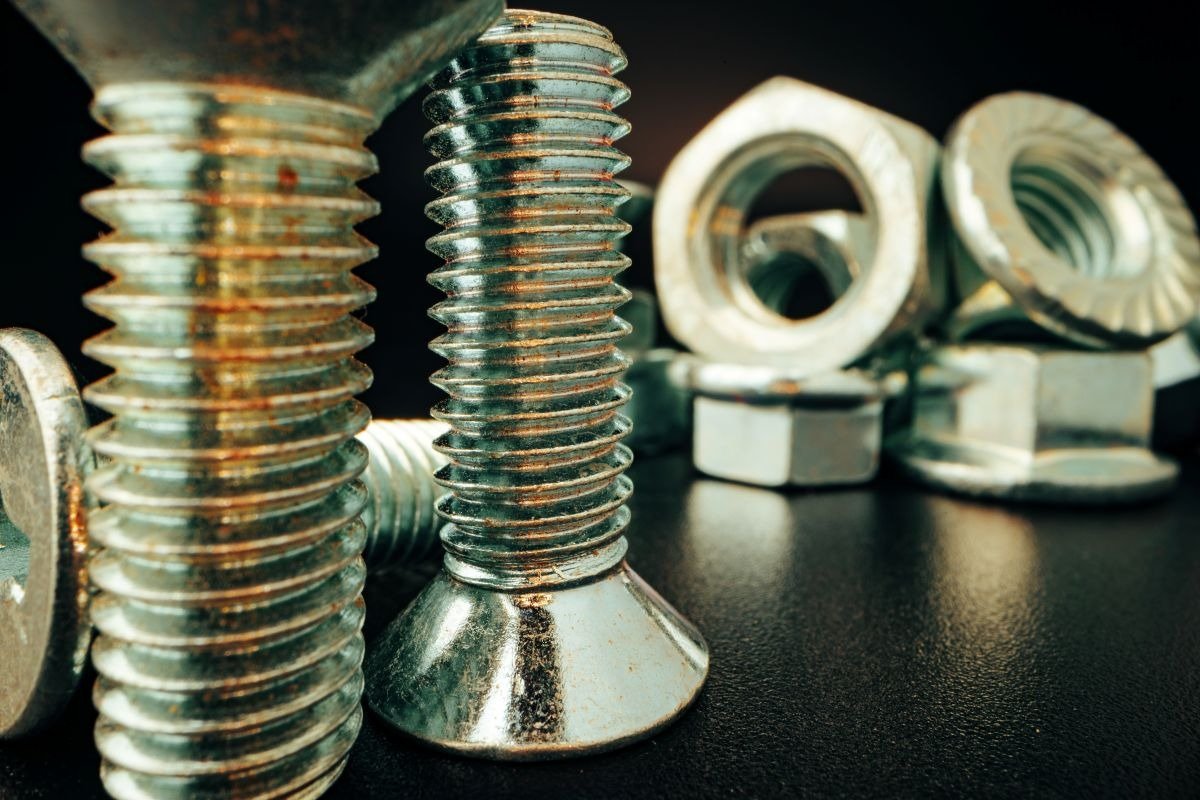

How to Choose the Right Bolt?

The success of a bolt installation depends not only on

correct direction and force but also on the initial selection of the bolt. How

to choose the right bolt becomes a key question at this point.

Environmental conditions, exposure to load, and the characteristics of the

mounting surface should be considered. For instance, stainless steel bolts are

ideal for outdoor systems, while carbon steel may suffice for indoor

applications. Additionally, the length and diameter of the bolt are critical to

its load-bearing capacity. Though it may seem like a minor detail, the thread

type also affects connection strength. Beyond right- or left-hand thread

options, selecting between metric and imperial sizes is also essential.

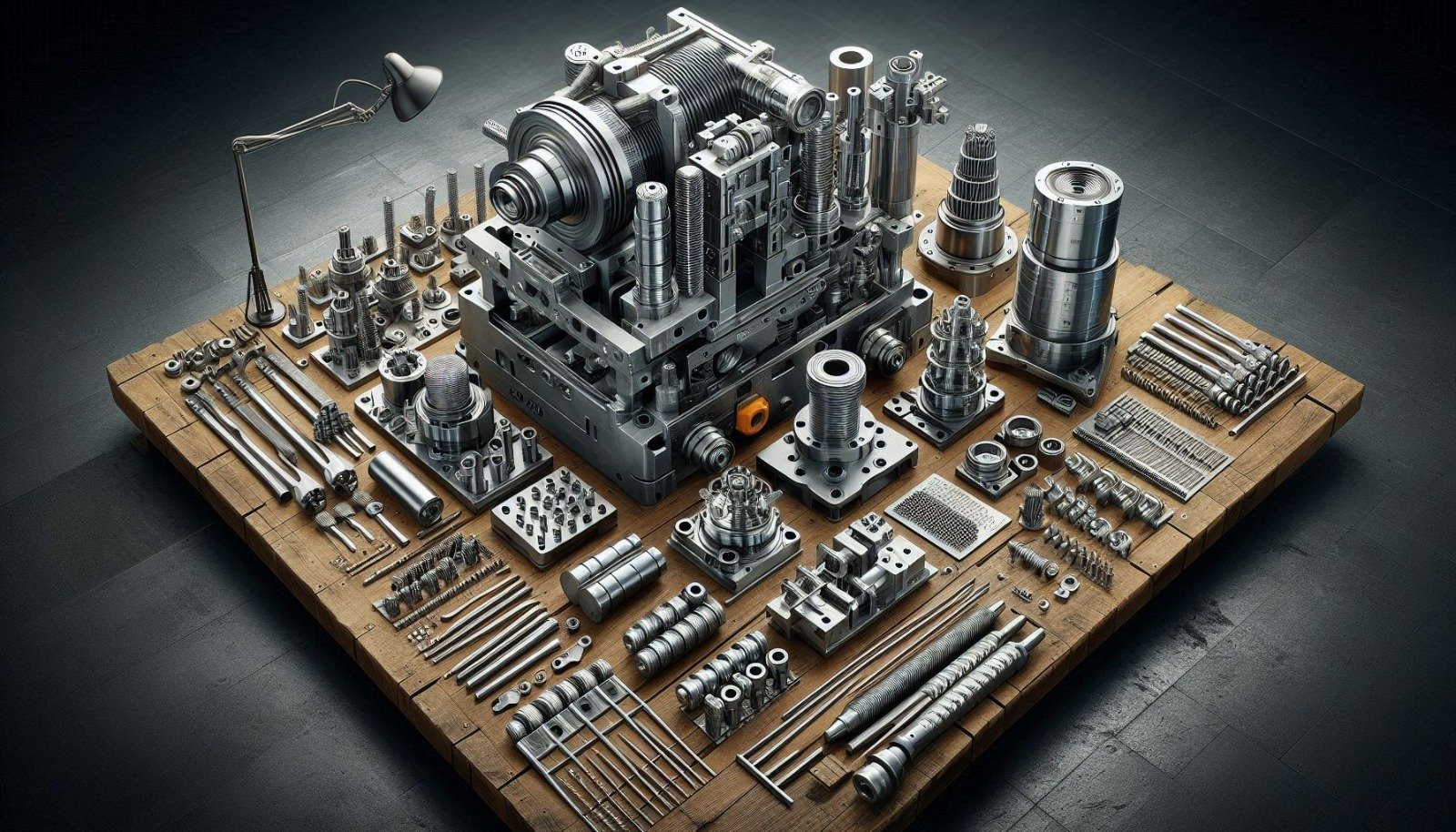

What Tools Are Used in Bolt Assembly?

What tools are used in bolt assembly? This question

brings attention to the essential equipment needed for bolt installation. Basic

tools include open-end wrenches, socket sets, and torque wrenches. The torque

wrench plays a life-saving role in precision work by providing feedback when

the correct torque is reached, preventing over-tightening. In some assemblies,

power tools like screwdrivers or drills may also be used. However, the most

critical point here is the quality and functionality of the tools. A worn-out

wrench may damage the bolt or fail to tighten it properly.

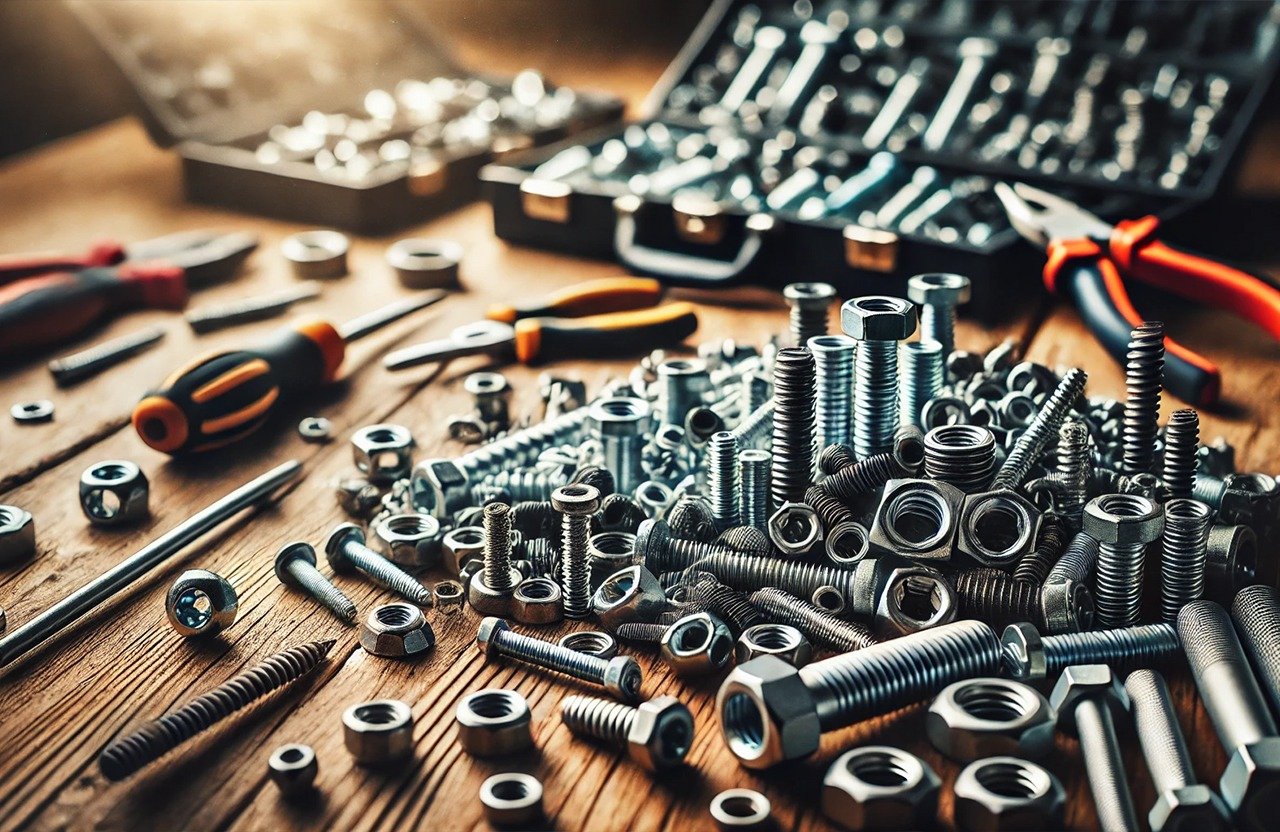

Common Bolt Tightening Mistakes

One of the most common issues during assembly is making

mistakes. That’s why knowing the common bolt tightening mistakes can be

a significant advantage. For instance, applying excessive force may deform both

the bolt and the connected parts. On the flip side, insufficient tightening can

lead to loosening over time and disrupt the connection. Other common mistakes

include improper contact between the bolt and the mounting surface, or

contaminants like oil or dirt being present during assembly. These oversights

can result in serious safety hazards. Therefore, it’s essential to clean the

surface and apply the correct torque using the proper tools before every

installation.