How Are Bolts Made?

Traditional Production in Fasteners: How Are Bolts Made?

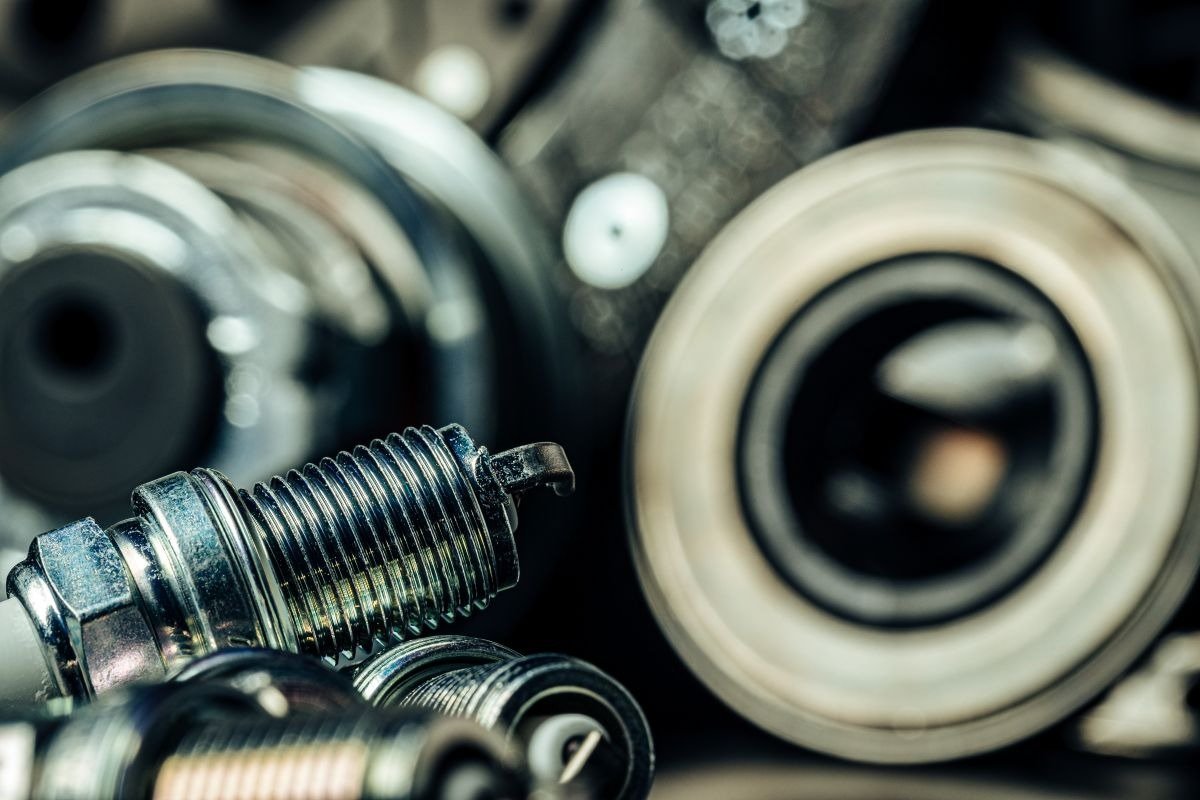

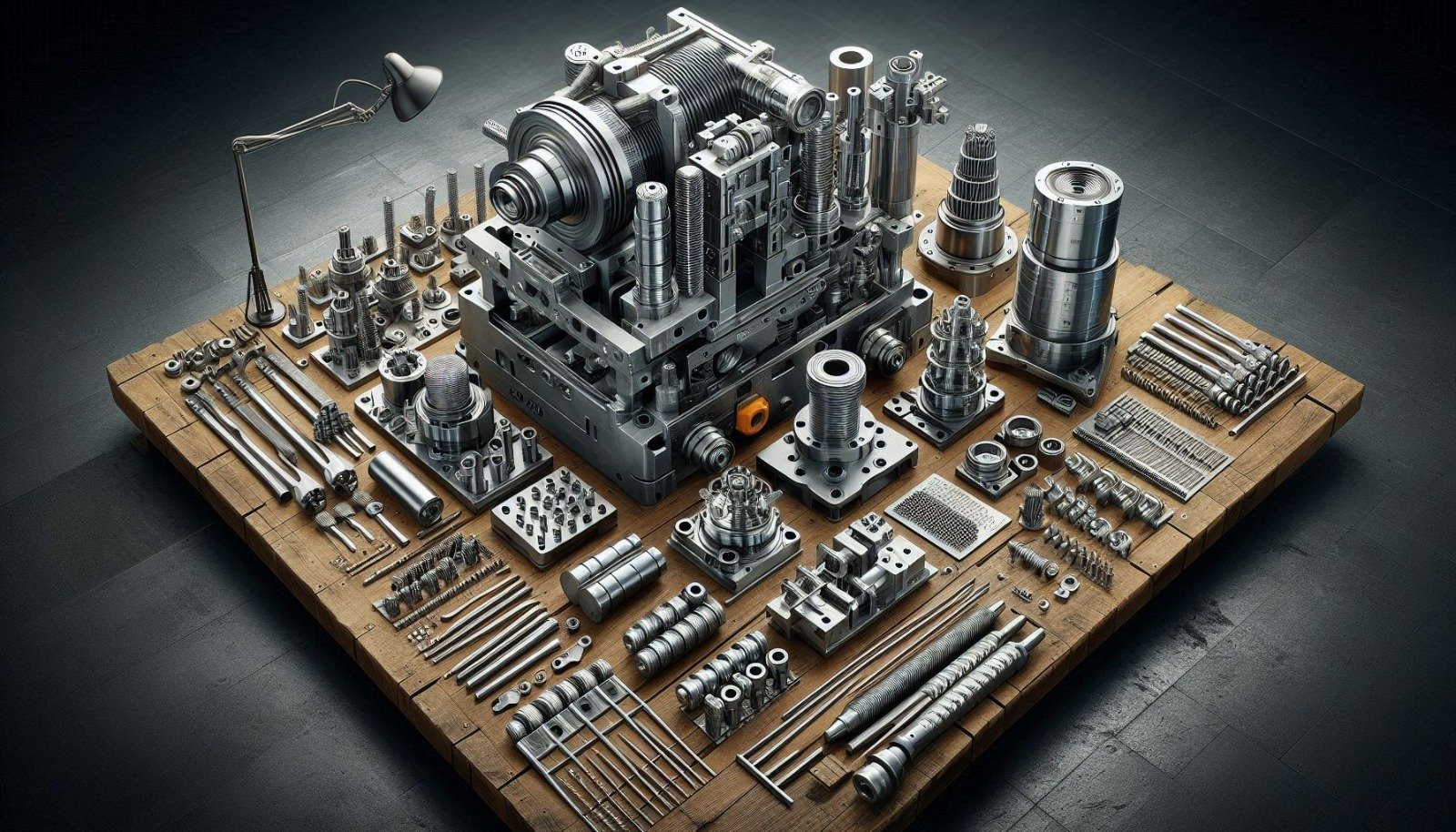

Fasteners are the backbone of the machinery and construction industries, serving as critical components in countless applications. Many of the products we use daily rely on bolts to ensure strength and safety. In this article, we’ll delve into the traditional production processes of bolts, focusing on globally recognized standard methods.

1. Material Selection

The first step in bolt production is selecting the right material. Carbon steel or stainless steel is commonly used due to its durability and resistance to environmental factors. The chosen material depends on the type of bolt and its intended application.

2. Manufacturing Process

a) Cold Forging Method

The traditional production of bolts predominantly employs the "cold forging" method, which is fast and efficient:

- Cutting: Steel wire coils are cut into pieces corresponding to the bolt size.

- Forging: The cut pieces are passed through multi-stage molds to form the head and other shapes.

- Thread Rolling: After forging, the bolt threads are formed using the thread rolling method.

b) Heat Treatment

To enhance the durability of bolts, heat treatment processes are applied. This step improves the hardness and strength of the bolts. For carbon steel bolts, "hardening and tempering" is commonly used.

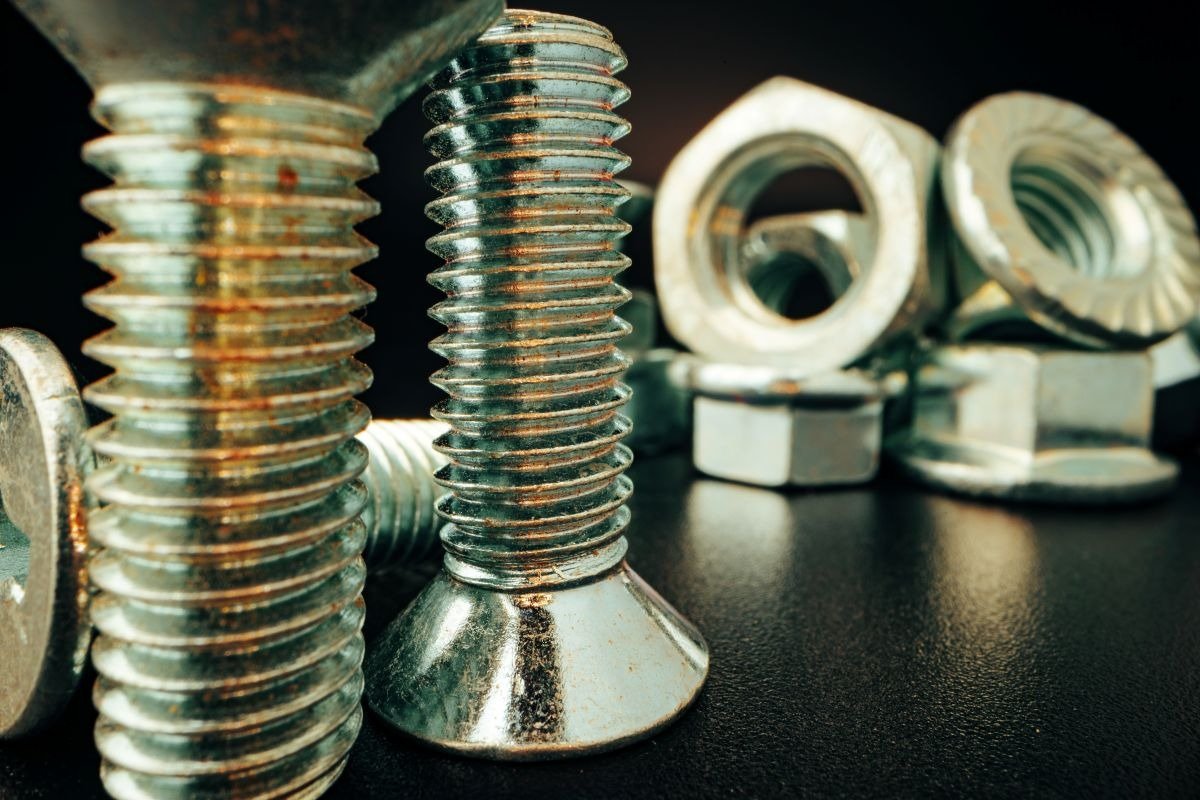

3. Surface Coating

Surface coating is performed to increase corrosion resistance and provide an aesthetic appearance. The most common coating types include:

- Galvanized Coating: Zinc is applied to the bolt surface to prevent rusting.

- Phosphate Coating: This method improves the paintability and lubrication of the bolt.

4. Quality Control

Each bolt undergoes rigorous quality control testing before leaving the production line. Load and torque tests, in particular, ensure that the product meets international standards.

5. Packaging and Shipping

In the final stage, the manufactured bolts are packaged appropriately for their intended use and prepared for shipment. The packaging process ensures the bolts are transported and stored without damage.

Conclusion

Traditional bolt production methods enable the reliable manufacturing of these critical fasteners, which require high precision and durability. From material selection to surface coating, every step directly affects the final product’s performance. As a result, traditional production techniques remain essential despite advancements in modern technologies.