How to Take and Calculate Bolt Measurements?

Bolt measurements are crucial in various industries, especially in construction, automotive, and manufacturing. Accurately measuring and calculating bolt dimensions is essential for proper fitting, safety, and functionality. Below is a comprehensive guide on how to take bolt measurements and calculate relevant dimensions.

1. Understanding Bolt Measurements

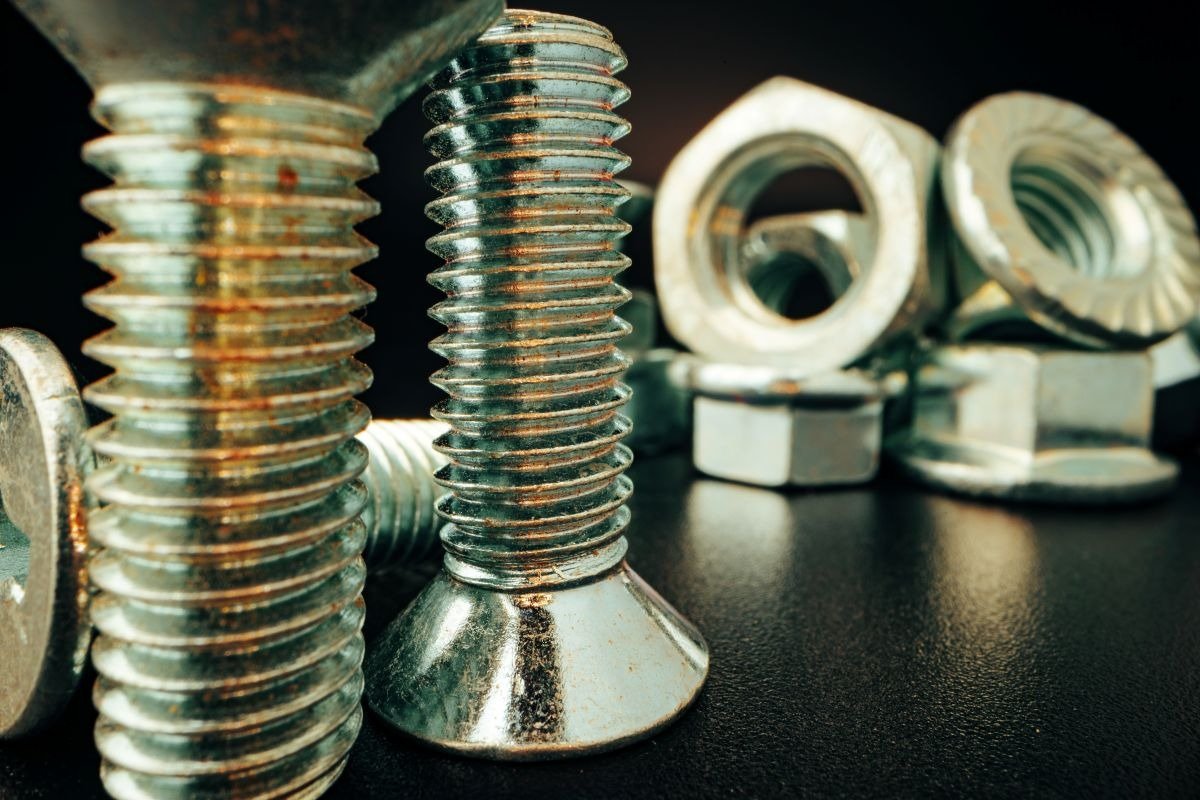

Bolts are measured based on several key dimensions:

- Diameter: The width of the bolt's shank, measured across its widest part. This is typically measured in millimeters or inches.

- Length: The distance from the tip of the bolt to the underside of the head. For bolts with a flat or countersunk head, the length is measured from the top of the head.

- Thread Pitch: The distance between threads, measured in millimeters (for metric bolts) or as the number of threads per inch (for imperial bolts).

- Head Size: The size of the bolt head, usually measured across the flats (the distance between two opposite sides).

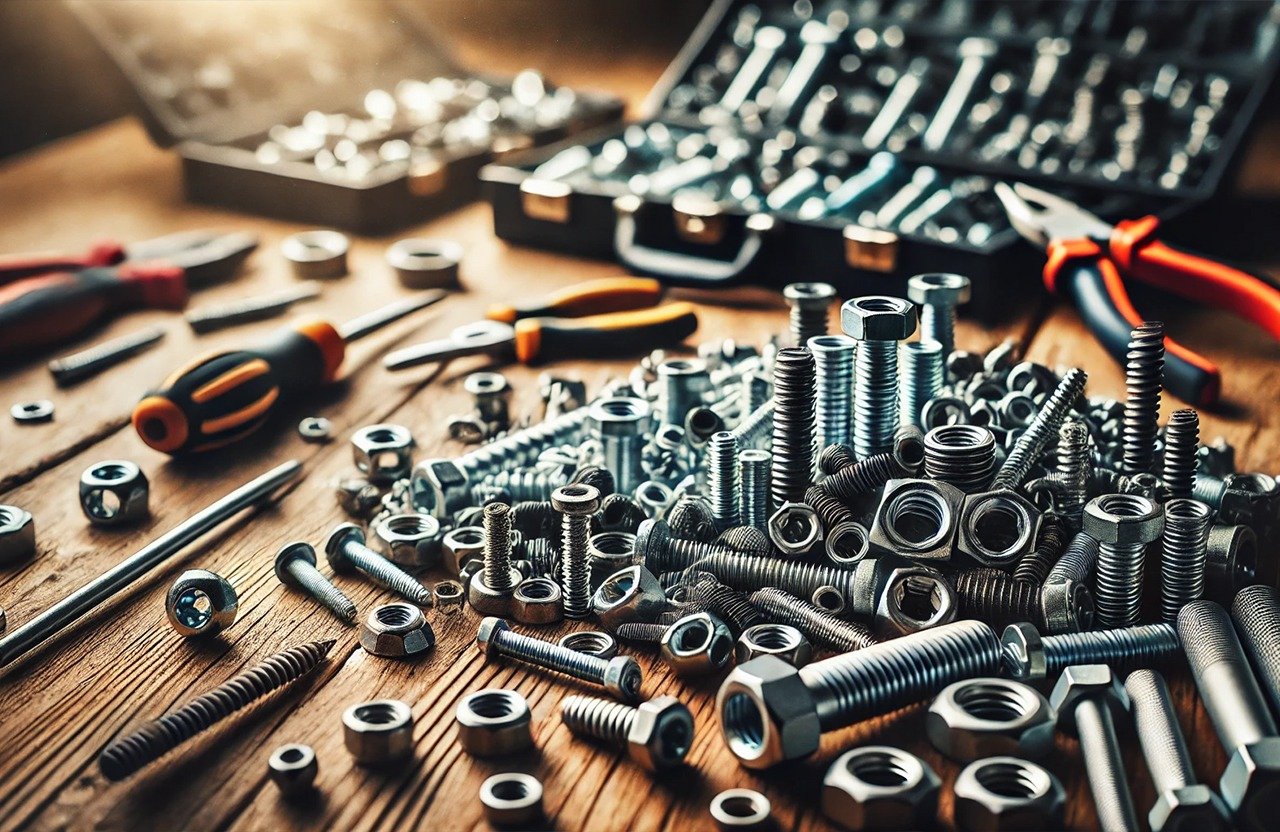

2. Tools Needed for Measurement

To measure a bolt accurately, you will need:

- Caliper: For measuring the diameter and head size.

- Ruler or Tape Measure: For measuring the length.

- Thread Gauge: To determine the thread pitch.

3. How to Measure Bolt Diameter

- Use a caliper to measure the diameter of the bolt shank.

- If the bolt has threads, measure the major diameter, which is the distance across the bolt’s threads at their widest point.

4. Measuring Bolt Length

- Place the bolt alongside a ruler or tape measure.

- Measure from the base of the head to the end of the bolt for bolts with a protruding head.

- For countersunk bolts, measure the entire length from tip to tip.

5. Determining Thread Pitch

- Use a thread gauge by placing the gauge against the threads of the bolt and finding the gauge that fits snugly between the threads.

- For metric bolts, the pitch is measured in millimeters per thread.

- For imperial bolts, count the number of threads within a one-inch section.

6. Practical Tips for Accurate Measurement

- Always ensure the bolt is clean and free of any debris before measuring.

- Double-check measurements, especially when dealing with critical components.

- Use precision tools like digital calipers for the most accurate measurements.

7. FAQs About Bolt Measurements

- Q: What is the difference between coarse and fine thread bolts?

- A: Coarse thread bolts have fewer threads per inch, making them quicker to fasten, whereas fine thread bolts have more threads per inch, providing better grip and strength.

- Q: How do I choose the right bolt size?

- A: Choose a bolt size based on the application, ensuring it matches the diameter, length, and thread pitch required for a secure and effective fit.

Understanding how to accurately measure and calculate bolt dimensions is vital for ensuring the proper fit and function in any mechanical or structural application. By mastering these measurement techniques and calculations, you can ensure that your projects are both safe and reliable.