The Importance and Types of Surface Coatings in Fasteners

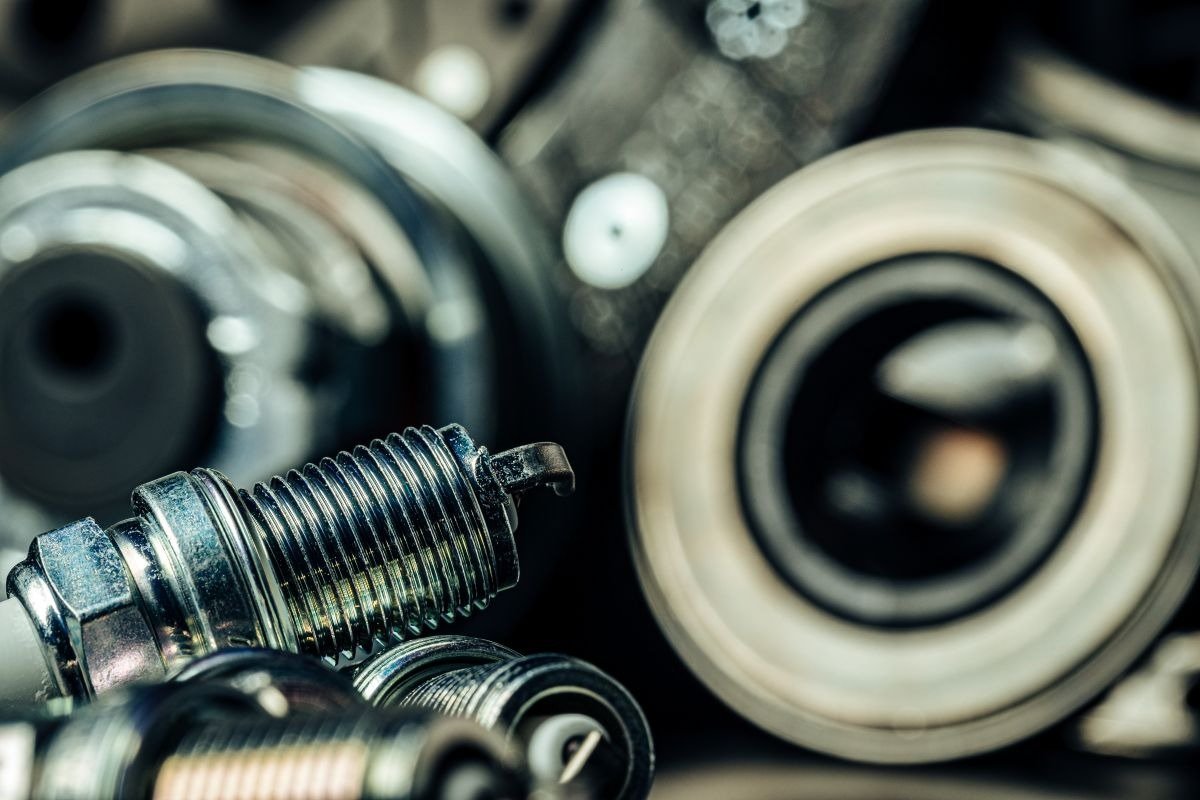

Fasteners play a critical role in various industrial sectors such as construction, automotive, and machinery. The durability and performance of these components depend not only on the material used but also on their surface coatings. Surface coatings protect fasteners against corrosion, enhance their mechanical properties, and provide an aesthetic appearance. So, what is the importance of surface coatings, and what types are there?

Fasteners are exposed to various chemical and physical effects depending on their working environments. Factors like moisture, saltwater, acids, and bases can cause metals to corrode. Corrosion weakens the structure of the material, leading the fastener to lose its function. This can jeopardize the safety of structures and result in significant costs. This is where surface coatings come into play.

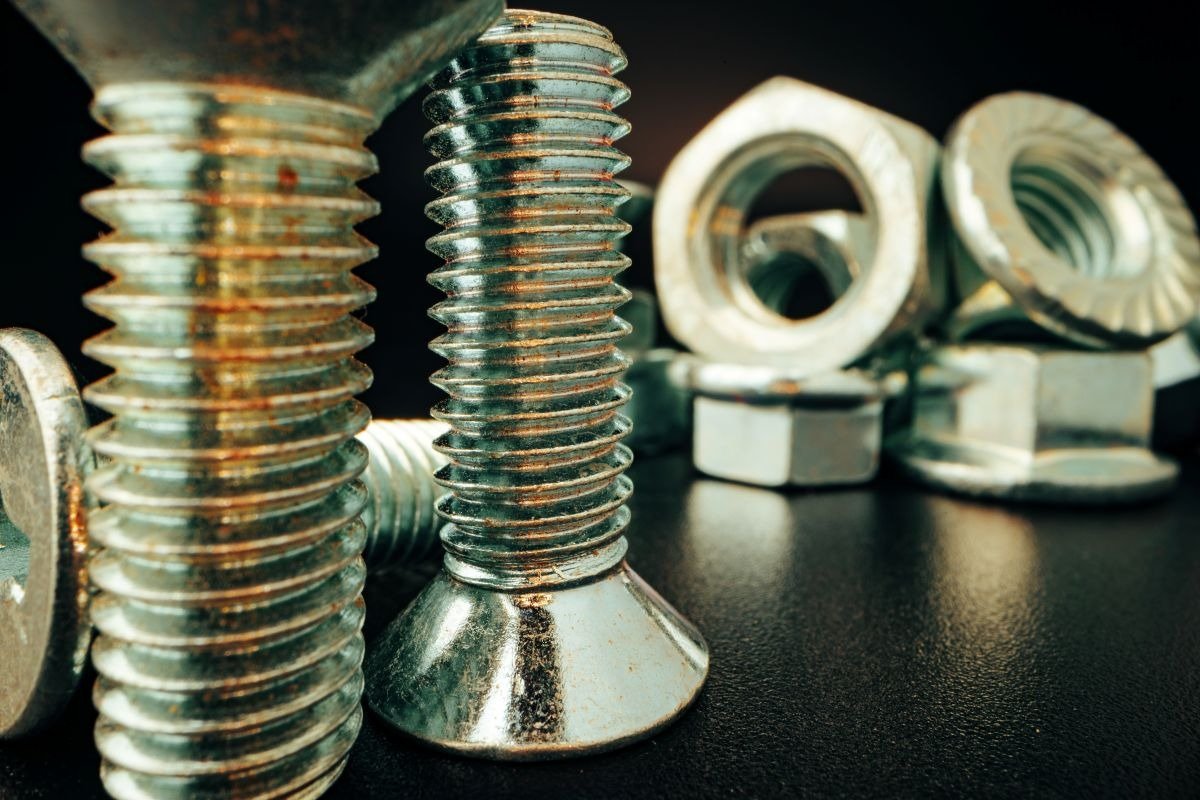

Surface coatings extend the lifespan of fasteners by protecting them against external factors. They also reduce the coefficient of friction, making assembly processes easier and increasing the reusability of fasteners. The type and quality of coatings should be selected according to the application area and requirements.

Zinc Coating (Galvanization):

One of the most commonly used surface coating types is zinc coating. Zinc prevents corrosion on iron and steel and is an economical solution. There are two main methods: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing involves immersing the fastener in molten zinc, providing a thicker coating. Electro-galvanizing creates a thinner layer of zinc through an electrolytic process.

Cadmium Coating:

Cadmium coating is used in harsh environments like marine and aerospace applications. It offers high corrosion resistance and a low coefficient of friction. However, due to the toxicity of cadmium, its use is decreasing and is restricted by environmental regulations.

Nickel Coating:

Nickel coating provides an aesthetic appearance and a hard surface. It increases corrosion resistance and improves electrical conductivity. It is preferred in electronic and decorative applications.

Phosphate Coating:

Phosphate coating creates a micro-porous structure on the surface, allowing paints and oils to adhere better. It offers moderate protection against corrosion and is generally used as a pre-treatment before painting.

Dacromet and Geomet Coatings:

These coatings are formed by combining zinc and aluminum flakes with a binder. They offer high corrosion resistance and heat resistance. They are widely used in the automotive and construction industries.

Teflon (PTFE) Coating:

Teflon coating provides a low coefficient of friction and high chemical resistance. It is resistant to high temperatures and facilitates the assembly of fasteners. It is preferred in the chemical industry and high-temperature applications.

Anodic Oxidation (Anodizing):

This is a coating method used for aluminum fasteners. It forms a protective oxide layer on the surface, increasing corrosion resistance and surface hardness. It also offers an aesthetic appearance and can be applied in different colors.

Copper and Tin Coating:

Copper coating is used to increase electrical conductivity, while tin coating improves solderability and corrosion resistance. They are widely preferred in electronic and electrical applications.

Considerations in Selecting Surface Coatings:

- Application Area: The selection of the coating depends on the environment in which the fastener will be used. Suitable coatings should be chosen for special conditions like seawater, chemicals, or high temperatures.

- Mechanical Properties: The coating should not affect the mechanical properties of the fastener. Thick coatings can change thread tolerances and cause assembly issues.

- Environmental Effects: Some coating materials can be toxic and subject to environmental regulations. Environmentally friendly alternatives should be preferred.

- Cost: The cost of the coating should align with the project's budget. Long-term performance and maintenance costs should also be considered.

Surface coatings in fasteners are of critical importance in terms of performance and durability. The correct choice of coating extends the product's lifespan, increases its reliability, and reduces overall costs. Therefore, selecting coatings appropriate to the project requirements and working conditions is of great importance.

By choosing fasteners with the most suitable surface coatings for your projects, you can enhance quality and safety. Do not hesitate to contact our expert team for the right choices.