Eco-Friendly Production: How Does Sustainable Bolt Manufacturing Work?

In today's world, environmental issues and climate change deeply affect all sectors, including the bolt manufacturing industry. The concept of sustainability has evolved from being just a trend to becoming a critical factor for the long-term success of businesses. So, how can eco-friendly and sustainable practices be implemented in bolt manufacturing?

The first step towards sustainability in bolt manufacturing begins with the selection of raw materials. Traditional production methods often require intensive use of natural resources, whereas utilizing recycled materials helps preserve these resources. Recycling not only reduces the need for raw materials but also significantly decreases energy consumption and carbon emissions. For instance, using recycled steel can reduce energy consumption in the production process by up to 75%.

Energy efficiency is another crucial element of sustainable production. Employing renewable energy sources in production facilities is an effective way to reduce the carbon footprint. Renewable energy technologies like solar panels and wind turbines can meet a significant portion of a factory's energy needs. Additionally, using energy-efficient machinery and equipment further reduces energy consumption and lowers operational costs.

Efficient use of water resources and waste management are indispensable components of eco-friendly production. Minimizing water consumption in production processes, implementing water recovery systems, and treating wastewater reduce environmental impacts and establish a sustainable production model. In waste management, recycling metal scraps and other waste materials generated during production is of great importance.

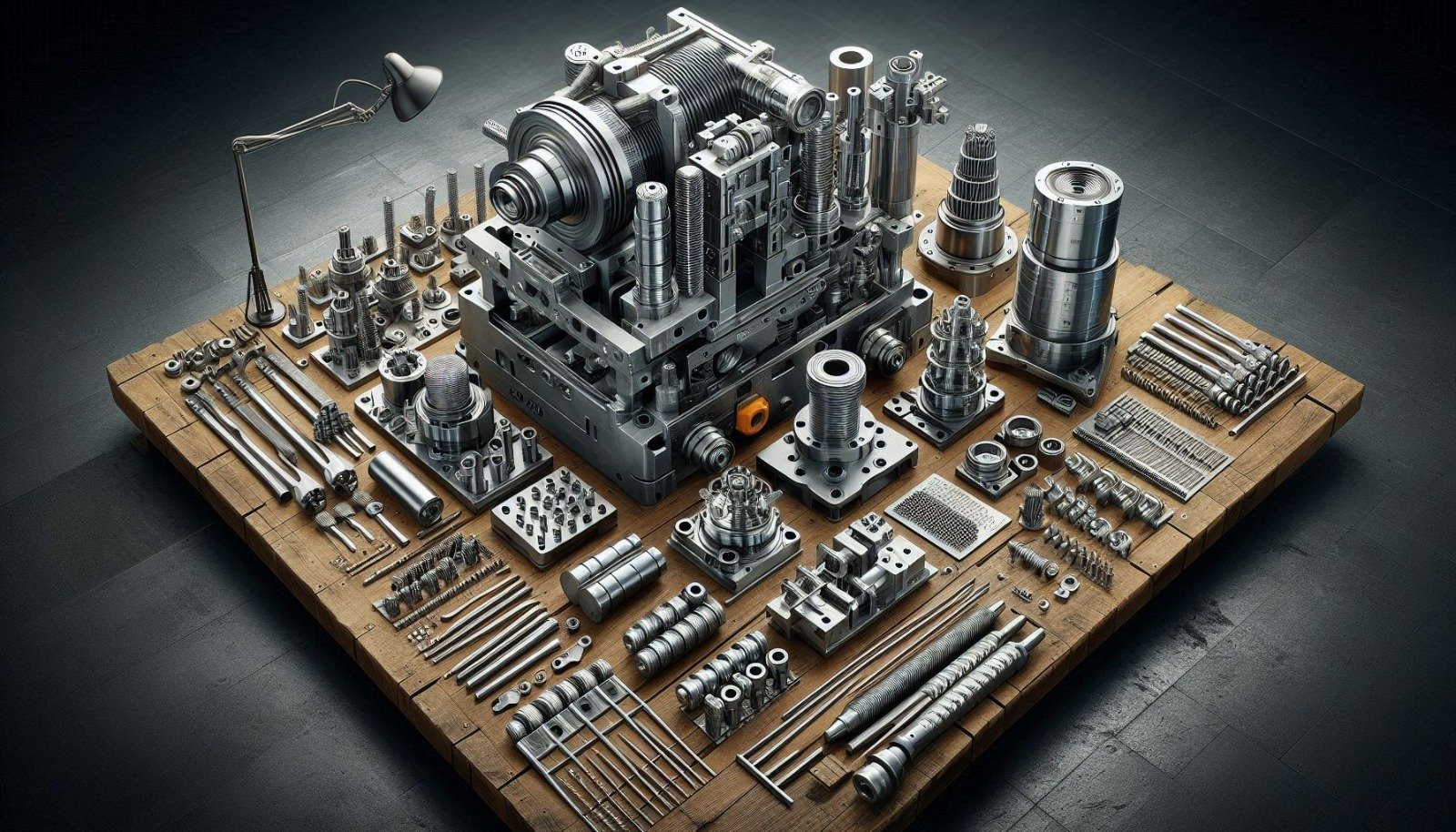

Technological innovations and modern production techniques contribute significantly to sustainable bolt manufacturing. Advanced production methods like 3D printing reduce material waste while increasing production efficiency. Automation and digitalization allow for more precise control of production processes, optimizing energy and raw material consumption. These technological advancements also help improve product quality and minimize production errors.

Implementing sustainability principles at all stages of the supply chain is critically important. Collaborating with suppliers who have adopted sustainable practices reduces the overall environmental impact of the production process. In logistics, optimizing transportation methods and routes decreases carbon emissions during shipping. Working with local suppliers or choosing transportation methods that consume less fuel are steps that can be taken in this area.

Employee training and involvement are vital for the success of sustainable production. For eco-friendly practices to be effectively implemented, employees need to be educated and take responsibility in these areas. Regular training programs, workshops, and awareness campaigns can increase employees' environmental consciousness. Moreover, employees should be encouraged to provide suggestions on process improvement and sustainability.

Complying with international standards and certifications is important for demonstrating a company's commitment to sustainability. Environmental management systems like ISO 14001 help businesses continuously improve their environmental performance. Holding such certifications serves as an indicator to customers and business partners that the company has adopted environmentally friendly practices.

Applying sustainability principles in product design also makes a significant difference. Designing bolts to be more durable and long-lasting extends the product's lifespan, reducing resource consumption. Additionally, producing products from recyclable or reusable materials contributes to the circular economy. This approach reduces waste while increasing customer satisfaction and brand value.

Sustainable bolt manufacturing not only provides environmental benefits but also offers economic advantages to businesses. Reducing energy and raw material costs, lowering waste management expenses, and increasing efficiency positively impact a company's profitability. Moreover, consumers' and business partners' demand for environmentally friendly products and services is steadily increasing. Businesses that can meet this demand gain a competitive edge in the market.

Bolt manufacturers who act with a forward-looking vision can lead the industry by taking steps toward sustainability. Adopting eco-friendly production methods is not just a legal and ethical obligation but also a strategic necessity for the long-term success of businesses. Every sector has responsibilities in combating climate change and environmental issues, and bolt manufacturing is no exception.

In conclusion, sustainable bolt manufacturing encompasses a wide range of practices, from using environmentally friendly raw materials to energy efficiency, from waste management to employee awareness. Implementing these practices helps businesses minimize their environmental impact, reduce costs, and strengthen their market position. For a more livable world, adopting and promoting sustainability-focused production methods is of great importance.