Types of Nuts: When to Use Which Nut?

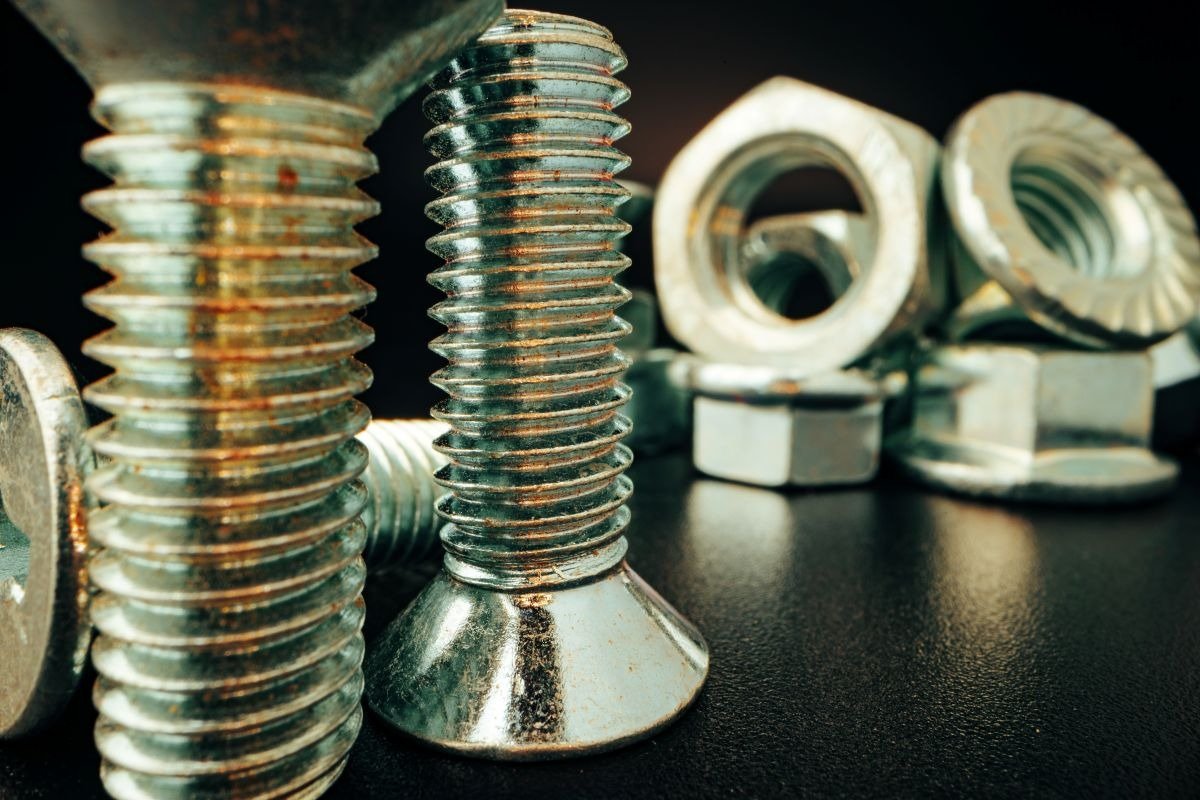

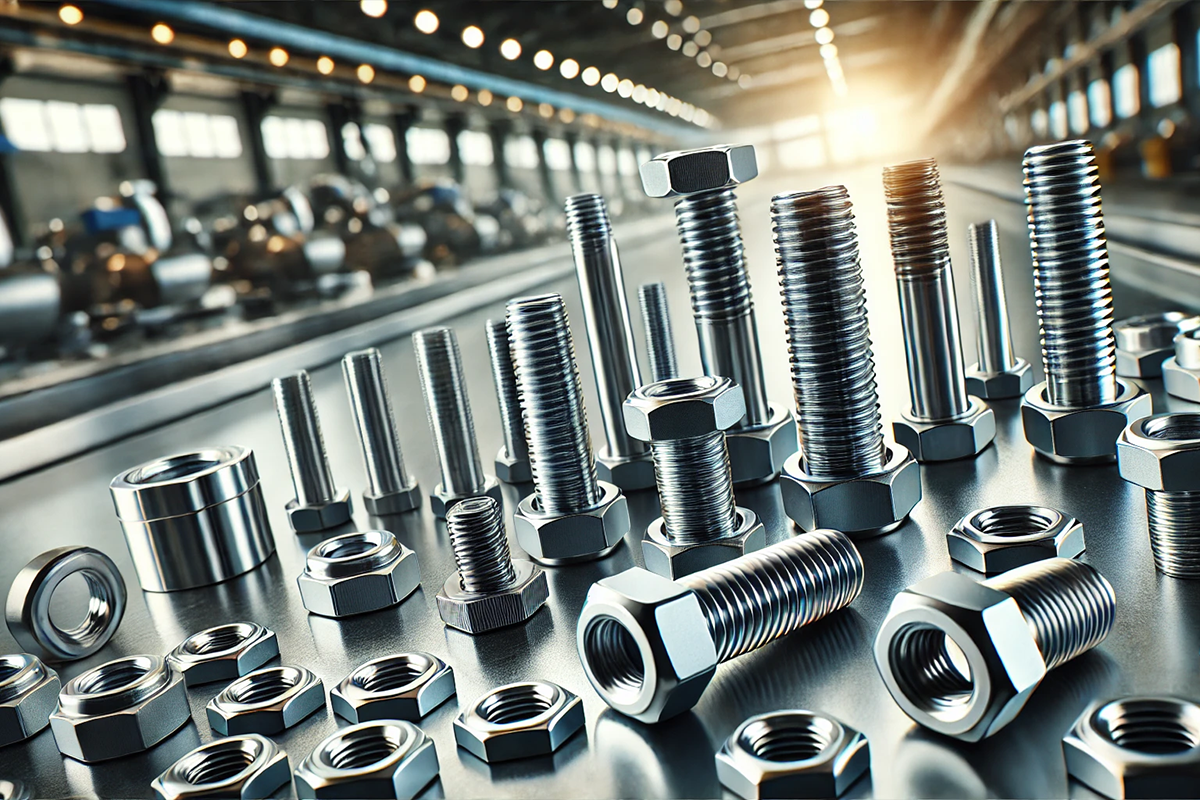

Nuts, the indispensable complement to screw systems, are

small yet powerful components that many people encounter daily without even

realizing their purpose. Simply tightening a screw is not enough for a secure

fastening; what truly holds the system together and ensures its reliability is

the nut bolt combination. The world of these small mechanical heroes is

far richer than it appears. Nut types and names, each designed for a

specific function, play essential roles in fields ranging from engineering and

furniture to the automotive and construction industries.

What Are the Types of Nuts?

Although they may initially seem like simple counterparts to

screws, nuts come in many varieties. Each type is designed for a specific

purpose and gains unique characteristics based on its area of application.

While the most common models include hex nuts, there are many others such as

castle nuts, square nuts, closed nut, fiber nut, and lock nut

types. Among these is the Flanged nut, which stands out with its

unique thread structure and surface design. Choosing the right one among these

options is vital for both safety and durability.

Where Are Nuts Used?

Nuts have a wide range of applications. They are used in

many places throughout daily life, often unnoticed. From automotive engine

blocks to bridge construction, from table legs at home to factory

machinery—nuts are everywhere. In areas with high vibration, lock nut types

are preferred to prevent the connection from loosening. For small household

items, small nut screw systems provide practical and secure connections.

Thanks to their easy installation, reusability, and durability, nuts are

considered the unsung heroes of modern engineering.

What Are Hex Nuts Used For?

Easily tightened or loosened with a wrench due to their

hexagonal shape, these are the most well-known and widely used type. They are

common in construction, furniture assembly, and automotive parts. When a

standard fastening solution is needed, this is often the first choice due to

its strength and cost-effectiveness.

What Are Castle Nuts Used For?

Named for their crown-like appearance, these special nuts

are secured with a cotter pin or wire. They are typically used in high-safety

applications such as aerospace and automotive industries, eliminating the risk

of the nut loosening on its own. Ideal for high-vibration environments.

What Are Square Nuts Used For?

Thanks to their four-sided shape, square nuts are used in

tight spaces or areas where rotation is undesired. While more common in older

systems, they are still used today in certain specialized machinery and

decorative metalwork. Their larger contact surface compared to hex nuts allows

for better load distribution.

What Are Flanged Nuts Used For?

With a wide, washer-like surface at the base, a Flanged

nut fits better onto surfaces and prevents damage to the parts being

fastened. It also reduces the risk of loosening. Commonly used in the

automotive industry for engine assembly or in vibrating environments, it offers

the dual function of washer and nut in a single piece—saving labor.

What Are Closed Nuts Used For?

This special type of nut has a closed end, offering both

aesthetic and functional benefits. Especially in outdoor connections, it

prevents the screw end from protruding, protecting against rust and providing a

safety advantage. Very useful in applications such as children's furniture. A closed

nut also gives mechanical systems a cleaner look.

What Are Fiber Nuts Used For?

Featuring a nylon insert that grips the threads when

tightened, fiber nut types are among the most practical lock nut

types. They ensure secure connections in vibrating environments. The nylon

insert adds resistance on the screw, making it harder to loosen over time. They

are used in electric tools, machinery, and even toy assemblies. A fiber nut

is both economical and reliable.

Advantages of Nuts

The biggest advantage of nuts is their ease of installation.

Their reusable structure makes them far more practical than other fastening

methods. They also stand out in terms of durability. Made from stainless steel,

brass, or galvanized metals, they resist harsh environmental conditions.

Additionally, thin nut types offered in various sizes enable secure connections even in tight spaces. This makes them indispensable in both industrial and home projects.

Additionally, thin nut types offered in various sizes enable secure connections even in tight spaces. This makes them indispensable in both industrial and home projects.

Important Considerations in Nut Usage

When choosing a nut, it’s important to consider not only the

shape but also the environment and purpose of use. For instance, a nut with

nylon content should not be used in high-temperature areas. Likewise, if used

outdoors, the nut should be made from corrosion-resistant materials.

Nut bolt compatibility is another critical point; the thread of the

screw must match the nut’s thread exactly. Otherwise, the connection will be

weak and may loosen or deform over time. Additionally, the correct torque

should be applied during assembly, as over-tightening can damage the threads.

These details are vital for the safety of the connection.