The Differences Between Bolts and Screws: Historical Development and Technical Details

Bolts and screws are fastening elements frequently used in our daily lives and industrial applications, but they are often confused with each other. Although both are used to hold objects together, they have significant differences in design, usage, and function. In this article, we will examine the fundamental differences between bolts and screws, along with their historical developments.

Historical Background

The origins of screws and bolts date back to ancient times when humanity first needed mechanical fasteners. Screws were conceptually defined by the Greek mathematician Archytas around 400 B.C. Later, Archimedes (287-212 B.C.) laid the foundation for screw presses by using the principles of screws in water lifting devices. In the Middle Ages, screws played a significant role in woodworking and in presses used for olive oil or wine production.

Bolts, on the other hand, gained importance in later periods, especially with the Industrial Revolution. In the 18th century, Henry Maudslay invented the screw-cutting lathe, making the mass production of standardized screws and bolts possible. This development contributed to the rapid advancement of machine production and industrial assembly techniques.

Technical Differences

What is a Screw?

A screw is a fastening element with helical threads on a tapered or cylindrical shaft, often capable of self-tapping. The ends of screws are usually pointed or sharp, allowing them to penetrate materials easily. Screws are used to fasten materials like wood, plastic, or thin metal sheets, and often require access from only one side.

What is a Bolt?

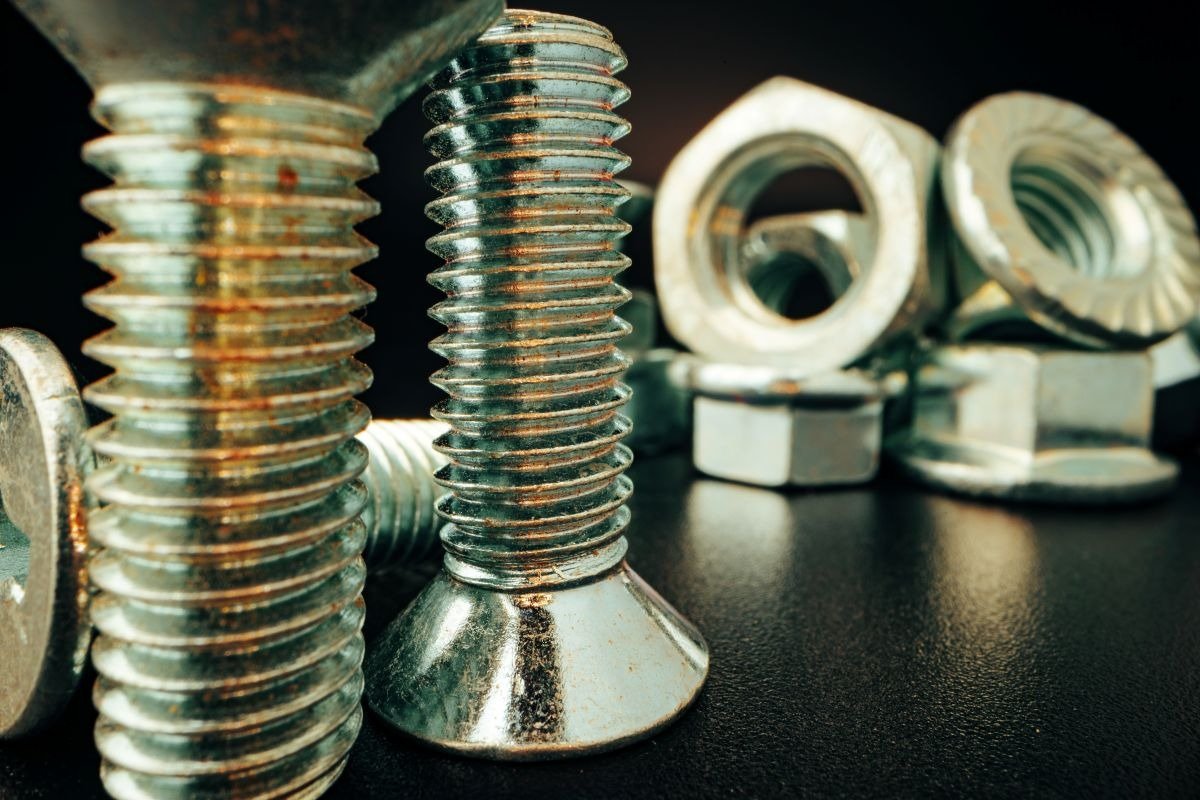

A bolt is a fastening element with standard threads on a cylindrical shaft, typically used in conjunction with a nut. The ends of bolts are flat and do not have self-tapping features. To hold two or more parts together, a combination of bolt, nut, and washer is used. Bolts are preferred in applications requiring high load-bearing capacity and tightness.

Usage and Applications

Use of Screws

Screws are widely used in joining various materials due to their self-tapping capabilities. Wood screws are commonly seen in furniture making, interior design, and construction. Sheet metal screws are effective in joining thin metal sheets. Screws are typically installed using a screwdriver or drill and do not require a pre-drilled hole.

Use of Bolts

Bolts are used in industrial applications where heavy loads and high stresses are involved. In the construction industry, they are indispensable in joining steel structures; in the automotive industry, they are used in engine and chassis assembly; and in the aerospace industry, bolts ensure the secure fastening of aircraft components. The bolt and nut combination enhances the strength and security of the connection.

Assembly and Disassembly

Screws

Screws are installed by directly screwing into the material. In this process, the screw cuts its own threads into the material or fits into existing threads. Removing and reinstalling screws, especially in soft materials, can damage the material's structure and weaken the connection.

Bolts

Bolts are assembled using the bolt head and a nut. This allows assembly and disassembly processes to be carried out more easily and without damaging the material. Additionally, bolts can be removed and reinstalled multiple times during maintenance and repair operations, which is a significant advantage in industrial applications.

Physical Characteristics and Design

Thread Structure: Screws have sharper and deeper threads, providing more grip when entering the material. Bolts have standard-sized threads designed to fit precisely with nuts.

Head Types: Screws can have various head types such as Phillips, slotted, hex, or Torx. This requires the use of different types of screwdrivers or bits. Bolt heads are generally hexagonal or square and are tightened with a wrench or socket set.

Materials and Coatings: Screws are typically made from steel, brass, or stainless steel. Zinc or nickel coatings can be used to enhance corrosion resistance. Bolts are made from high-strength steels and are usually protected with galvanization or special coatings.

Functional Differences

Load-Bearing Capacity: Bolts have a higher load-bearing capacity compared to screws and are therefore preferred in heavy-duty and critical connections.

Permanent vs. Temporary Connections: Screws are often used for permanent or semi-permanent connections, while bolts are used in connections that need to be frequently assembled and disassembled or require maintenance.

Vibration Resistance: Bolts are more resistant to vibration when properly tightened and when locking elements are used. Screws carry the risk of loosening in vibrating environments.

Selecting the Right Fastener

Choosing the right fastener is critical for the success and safety of your project. Consider the following factors:

Type of Material: The types and properties of the materials to be joined (wood, metal, plastic).

Load and Stress: The mechanical loads and stresses the connection will be subjected to.

Accessibility: Whether the assembly will be done from one side or both sides.

Maintenance and Repair Needs: The frequency of disassembly and reassembly and maintenance requirements.

Environmental Conditions: The effects of factors like corrosion, temperature, and vibration.

While bolts and screws are used for similar purposes, they have significant differences in design, function, and application areas. These fastening elements, which have evolved throughout history with technological advancements, have become indispensable parts of modern industry. Selecting the right fastener is vital for the safety, durability, and success of your project.

To learn more about the most suitable bolt and screw options for your project and to hear our expert team's recommendations, contact us.