Latest Bolt Technologies in the Industry

In today's rapidly evolving industrial environment, fasteners—and bolts in particular—play a critical role in the safety and efficiency of structures and machinery. Technological advancements have led to groundbreaking innovations in bolt design, materials science, and manufacturing techniques. In this article, we delve deep into the latest bolt technologies, examining their impact on various sectors and exploring their future potential.

High-performance materials are among the most significant innovations in bolt technology. Titanium alloys are preferred in aerospace, space, and medical applications due to their high strength-to-weight ratio. Nickel-based superalloys are used in gas turbines and power plants, exhibiting superior performance at extreme temperatures. Additionally, amorphous metals, with their atomic-level disordered structures, offer high hardness and elasticity. Composite and polymer materials also hold a crucial place in this field. Carbon fiber-reinforced polymers are used in automotive and sports equipment for weight reduction and high strength, while high-performance thermoplastics are ideal for applications requiring chemical resistance and electrical insulation.

Smart bolts and the integration of the Internet of Things (IoT) have ushered in a new era for fasteners. Sensor-integrated bolts enhance connection safety by monitoring stress and torque values in real-time. Vibration and temperature monitoring features help detect potential failures in industrial machinery beforehand. Thanks to data analytics and predictive maintenance applications, data from sensors can be stored in the cloud and analyzed to develop maintenance strategies using big data. Artificial intelligence and machine learning are employed to identify failure trends and optimize maintenance processes.

Advanced surface treatments and coatings play a significant role in bolt technology. Nanotechnology applications involve applying nano-coatings to surfaces to increase corrosion resistance and reduce friction. Antimicrobial coatings are used to reduce infection risks in medical devices. Self-lubricating coatings, solid film lubricants, and polymer coatings make assembly and disassembly processes easier by reducing the coefficient of friction.

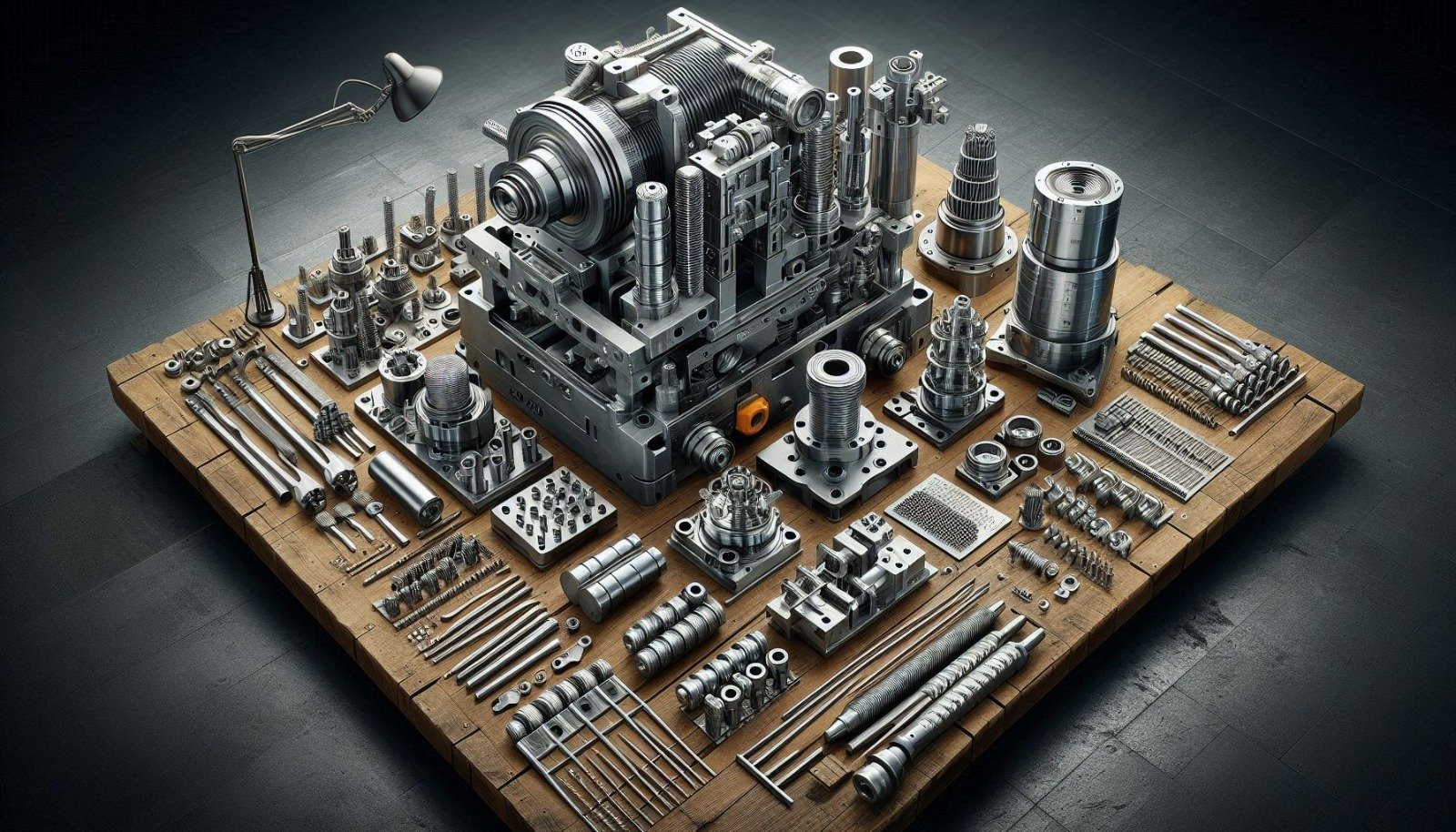

Additive manufacturing and 3D printing technologies enable the creation of customized and complex geometries in bolt production. Through topological optimization, material usage is optimized using computer-aided design, producing lighter and stronger bolts. Internal channel structures allow for voids or channels within bolts for cooling or weight reduction purposes. 3D printing technologies contribute to environmental sustainability by reducing production times and minimizing material waste.

Updated standards and certifications are another important aspect of developments in bolt technology. Changes in international standards bring new mechanical and physical property requirements for high-strength bolts. Updates like ISO 898-1 and DIN EN 14399 are significant examples. ASTM standards offer new protocols regarding material quality and testing methods. Additionally, environmental and sustainability standards like RoHS and REACH compliance limit the use of harmful substances, protecting human health and the environment.

Robotics, automation, and artificial intelligence are revolutionizing bolt assembly and manufacturing processes. Automated assembly and control systems minimize human error by performing highly precise bolt assembly using robotic arms and image processing systems. AI-supported design and manufacturing increase production line efficiency through generative design and process optimization, predicting failures in advance.

The applications of these technologies across sectors are extensive. In the aerospace and space industry, light and durable bolts reduce weight while enhancing safety in aircraft and spacecraft structures. In the automotive industry, special bolts providing high conductivity and reliability are used in the battery connections of electric vehicles. In the construction and infrastructure sector, earthquake-resistant connections enable structures to withstand seismic activities, and IoT-integrated bolts in smart buildings monitor structural health to determine maintenance and repair needs.

Looking ahead, advancements in materials science hold significant promise. Graphene and two-dimensional materials offer new application areas with exceptional mechanical and electrical properties. Biomaterials could revolutionize medical implants with biocompatible bolts. Quantum technologies and nanotechnology will be influential in shaping the fasteners of the future through atomic-scale manufacturing and smart materials.

In conclusion, these rapid and comprehensive developments in bolt technology offer significant opportunities across a wide range—from industrial production to construction, from automotive to aerospace. These innovations play a critical role in achieving safety, efficiency, and sustainability goals. It is crucial for businesses and industry professionals to closely follow these technologies and integrate them into their applications to gain a competitive advantage.