The Role of Trapezoidal Screws and Nuts in Industrial Applications

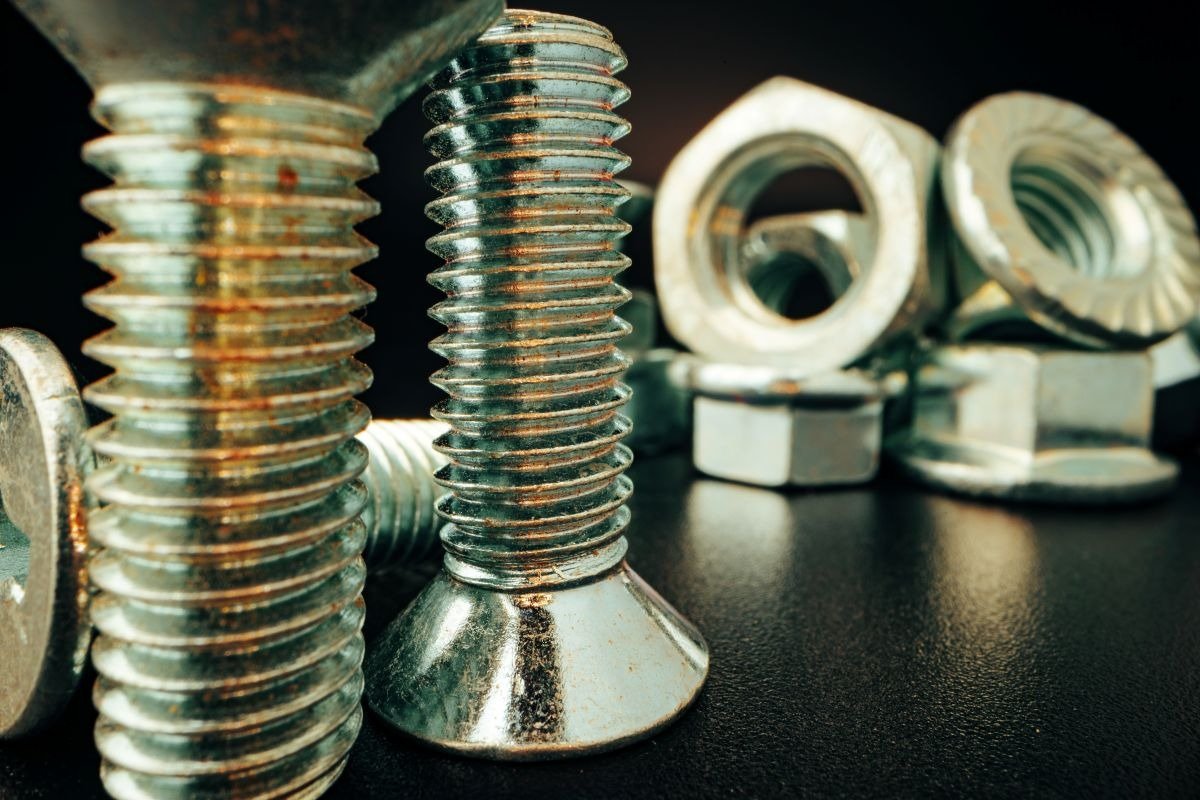

In the fields of mechanical engineering and industrial design, numerous components are designed to ensure the smooth operation of complex systems. One such component is the trapezoidal screw and nut system. Trapezoidal screws are a special type of screw used in many industrial applications to provide high precision, strong drive, and long service life.

Trapezoidal Screws: Structure and Use

A trapezoidal screw features a thread profile shaped like a trapezoid. This unique thread design stabilizes and ensures the reliability of the screw's movement. Trapezoidal screws are typically designed to operate at low speeds and under heavy loads. These characteristics make them a popular choice in CNC machines, conveying systems, and automation equipment.

A trapezoidal screw features a thread profile shaped like a trapezoid. This unique thread design stabilizes and ensures the reliability of the screw's movement. Trapezoidal screws are typically designed to operate at low speeds and under heavy loads. These characteristics make them a popular choice in CNC machines, conveying systems, and automation equipment.

The Function of the Nut

Nuts used with trapezoidal screws play a critical role by converting the rotational motion of the screw into linear movement. These nuts have threads that match the screw, allowing for the precise linear movement needed in many industrial applications, making them ideal for accurate positioning and transporting tasks.

Nuts used with trapezoidal screws play a critical role by converting the rotational motion of the screw into linear movement. These nuts have threads that match the screw, allowing for the precise linear movement needed in many industrial applications, making them ideal for accurate positioning and transporting tasks.

Application Areas

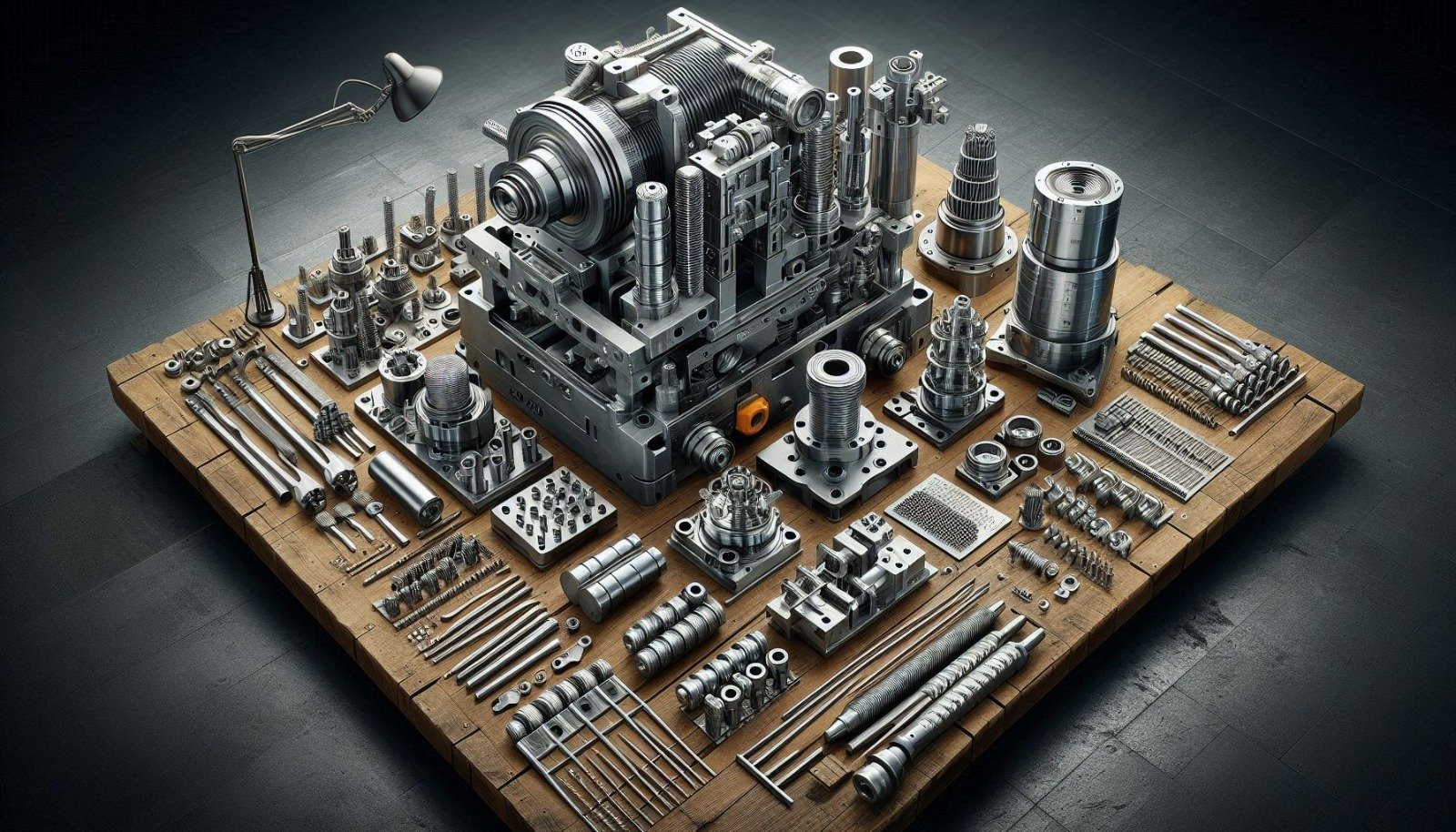

The combination of trapezoidal screws and nuts is widely used across various industrial sectors. They are essential for controlling moving parts in CNC machines, for precise positioning in 3D printers and laser cutting machines, and for carrying heavy loads in conveying systems. These systems are also commonly found in industrial robotics.

The combination of trapezoidal screws and nuts is widely used across various industrial sectors. They are essential for controlling moving parts in CNC machines, for precise positioning in 3D printers and laser cutting machines, and for carrying heavy loads in conveying systems. These systems are also commonly found in industrial robotics.

Advantages and Disadvantages

Trapezoidal screw and nut systems offer advantages such as high load-carrying capacity, long lifespan, low maintenance needs, and cost-effectiveness. However, in applications requiring high-speed movement, gear-driven systems might be more suitable as trapezoidal screws generally perform better at lower speeds.

Trapezoidal screw and nut systems offer advantages such as high load-carrying capacity, long lifespan, low maintenance needs, and cost-effectiveness. However, in applications requiring high-speed movement, gear-driven systems might be more suitable as trapezoidal screws generally perform better at lower speeds.