Ensure Efficiency in Your Construction Projects with the Right Screw Selection

When starting a new construction project, selecting the right type of screw is crucial. Each screw head and drive style is designed for specific applications. SCK Civata offers a clear explanation of the available screw heads and drive types to help you choose the most suitable screws for your project.

Importance of Screw Heads

Screw heads provide various functionalities for different applications. One of the oldest and most common screw heads is slotted, used with a flat-blade screwdriver. However, slotted screw heads have disadvantages, such as the screwdriver slipping or damaging the head easily.

Therefore, manufacturers have developed more functional screw heads for a wider range of applications. For example, the slotted and Phillips heads are the most commonly used in the United States. Having a wide variety of screw head options makes it easier to find screws suitable for specific applications.

Types of Screw Heads

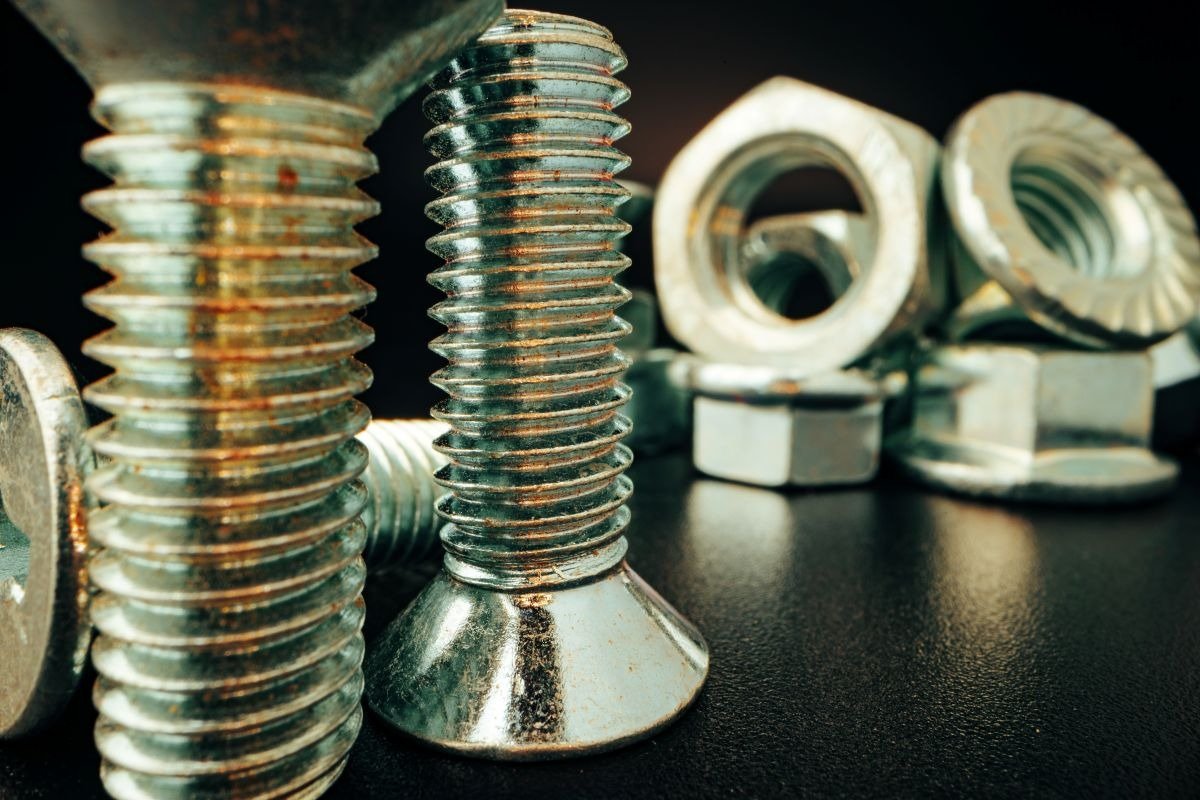

Screw heads are categorized into two main types: countersunk and non-countersunk screws.

Countersunk Screw Heads

Countersunk screws allow for flush mounting into the material due to the angled shape under the screw head.

- Flat Head: These screws are mounted flush with the surface of the material. They are used in many construction projects, including cabinets, countertops, stairs, and furniture.

- Oval Head: A combination of a countersunk and a domed head, these screws protrude slightly from the material surface and provide a decorative appearance.

- Bugle Head: These screws have a shape that reduces damage to the material they are driven into, distributing the stress over a wider area than flat-head screws. They are ideal for drywall and wood flooring applications.

Non-Countersunk Screw Heads

Non-countersunk screws have a flat underside and remain fully exposed on the surface once driven into the material.

- Binding Head: Similar to pan heads, these screws typically have a deep slot in the center of the head and a prominent undercut beneath the head, providing space for wire bindings. They are excellent for electrical applications.

- Button Head: Featuring a rounded head design, they are often used for socket driver recesses and Torx driver recesses.

- Dome Head: These screws sit nicely on the material's surface with a decorative appearance once installed.

- Pan Head: The most common type of round screw head, ideal for applications requiring a flat underside. They are often used to secure metal components like machine and automotive parts.

- Round Head: With a thicker decorative head, these screws provide an aesthetic look when installed.

- Fillister Head: These screws have long cylindrical sides and a slightly rounded top, making them suitable for deeper recesses compared to pan or round head screws.

- Truss Head: Featuring a wide, mushroom-shaped head, they typically have a lower profile and a broader bearing surface than round or pan heads, commonly used in sheet metal applications.

- Flange Head: Available with circular or hex heads, these screws have a circular flange directly under the head.

- Hex Head: These screws offer more torque and are typically installed with a wrench or socket. They are common in screws and bolts.

- Socket Head: With a cylindrical head, these screws are specific to socket driver recesses.

- Square Head: Featuring a square in the center of the head, they are common in screws and bolts.

Screw Drive Types

Like screw heads, there are many varieties of drive types. Screws require different driver types for proper installation and removal. The drive type typically consists of protrusions on the screw head. When the correct screwdriver or drill bit is inserted into the screw head, it grips these protrusions to help turn the fastener.

- Slotted: Widely used and easy to find, these screws have a single straight line across the screw head's center. Flat-blade screwdrivers or flat-blade drills are compatible.

- Phillips: Performing better with screwdrivers than flat drives, Phillips drives have four contact points, providing more torque for a tighter fit.

- Tamper-Resistant Phillips: Similar to the traditional Phillips drive but with additional security features.