What is Multi-Stroke Cold Forging Technology?

Multi-stroke cold forging technology is a process in which multiple successive impacts are applied to shape and deform metals. This technology provides precise control over the material and enables the production of highly complex parts. Widely used in high-volume production, this method stands out with its cost efficiency and quality advantages.

How Does Multi-Stroke Cold Forging Technology Work?

Multi-stroke cold forging technology utilizes specialized press machines that apply sequential impacts to shape the metal. This process plastically deforms the metal while preserving most of its material properties. The working principle of multi-stroke cold forging is generally as follows:

- The metal rod or wire to be used is usually pre-cut and coated with special lubricants.

- The material is placed into a cold forging press where successive impacts are applied through a multi-die system.

- After shaping, the part is cleaned, measured, and additional treatments are applied if necessary.

In this process, material deformation resistance and die precision play a crucial role.

Advantages of Multi-Stroke Cold Forging Technology

Forging is a manufacturing method that allows for rapid production speeds. The ability to perform multiple shaping processes simultaneously provides significant advantages, especially in mass production. This method ensures that forged parts acquire precise dimensions, reducing the need for machining and minimizing material waste. It also reduces energy consumption, leading to cost savings. Since the internal structure of the material becomes more compact during the process, the durability of the product significantly increases. Additionally, this method is environmentally friendly due to its low energy consumption.

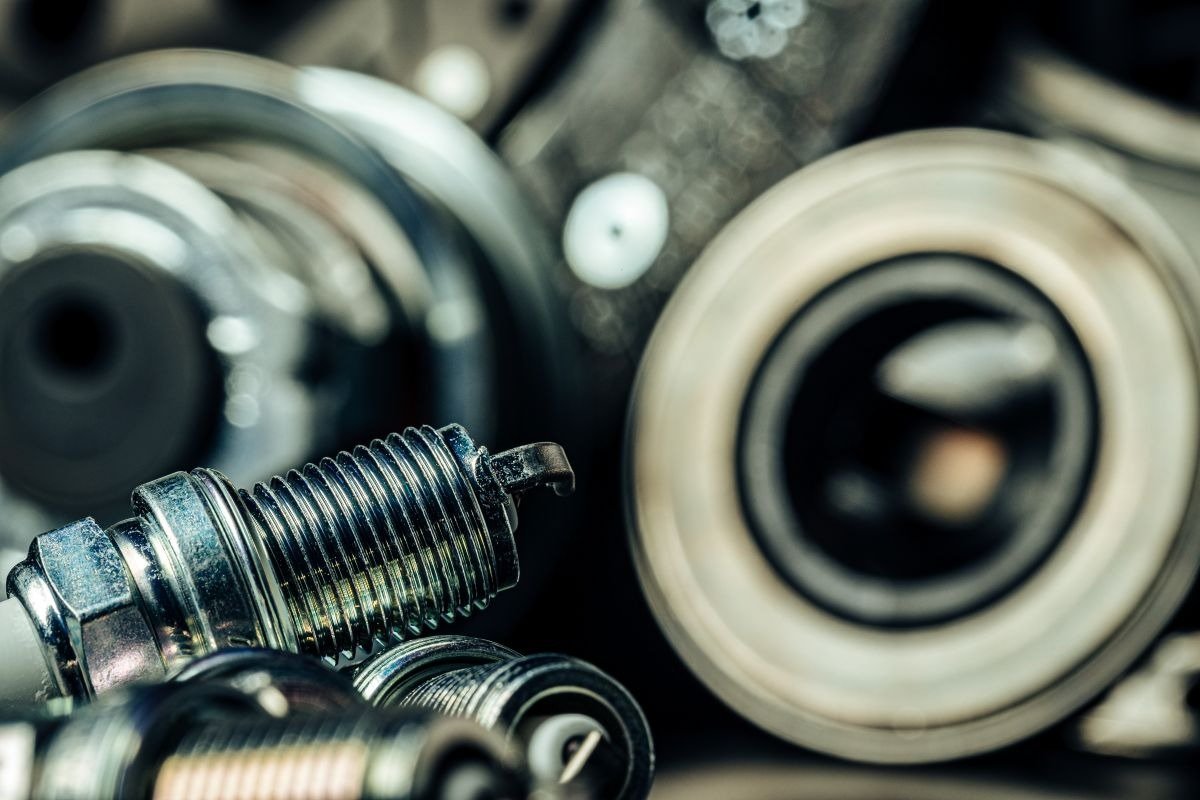

Applications of Multi-Stroke Cold Forging Technology

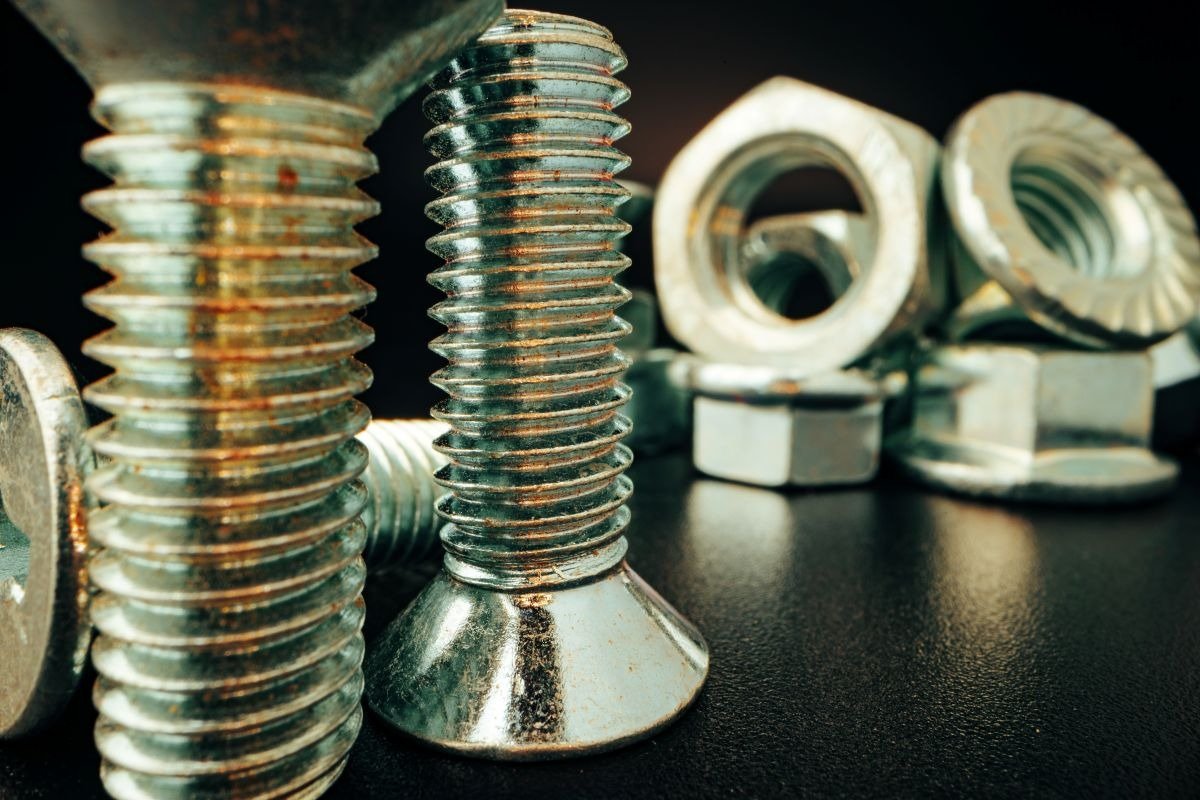

This technology is widely used in industries such as automotive, aerospace, home appliances, and electronics. It is mainly preferred for producing standard or custom-designed fasteners such as screws, bolts, and pins. Additionally, it is suitable for shaping mechanical components like gears and axles. Metal clips, nails, and other fastening elements can also be efficiently manufactured using this method. The following processes commonly utilize this technology:

- Shaping of standard or custom-designed fasteners such as screws, bolts, and pins.

- Manufacturing of mechanical components like gears and axles.

- Production of fastening elements such as metal clips, nails, and connectors.

This method is ideal for situations where a large number of identical parts need to be produced quickly and efficiently.

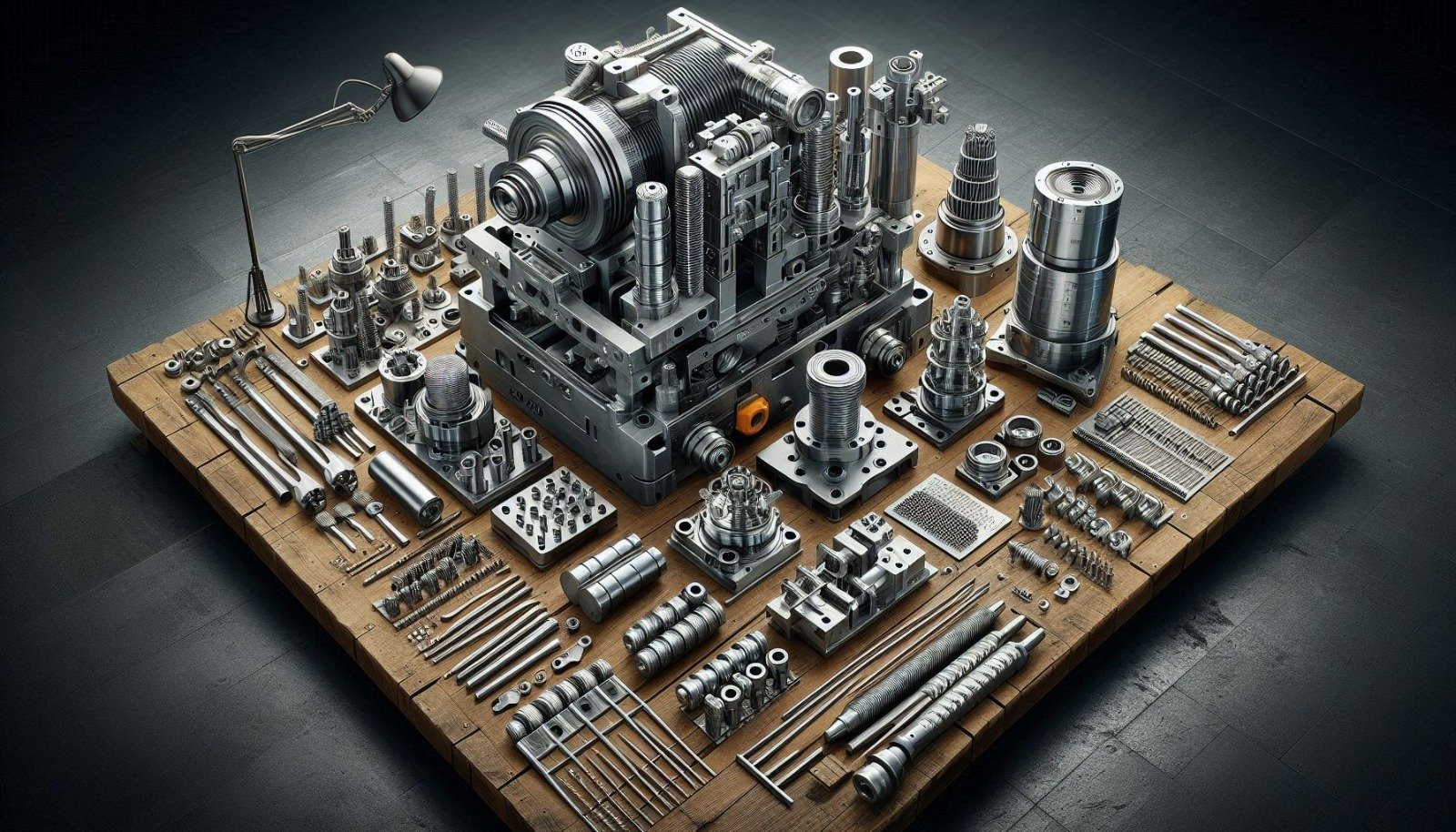

Equipment and Machines Used in Multi-Stroke Cold Forging Technology

The main equipment used in cold forging processes includes multi-station press machines known as cold forging presses. Guide dies play a crucial role in precisely shaping the metal. Lubrication and cooling systems help control the heat generated during the process. Additionally, various inspection and measurement tools are used to ensure the precision of the manufactured parts. The integration of these components allows for high efficiency and superior accuracy in production.