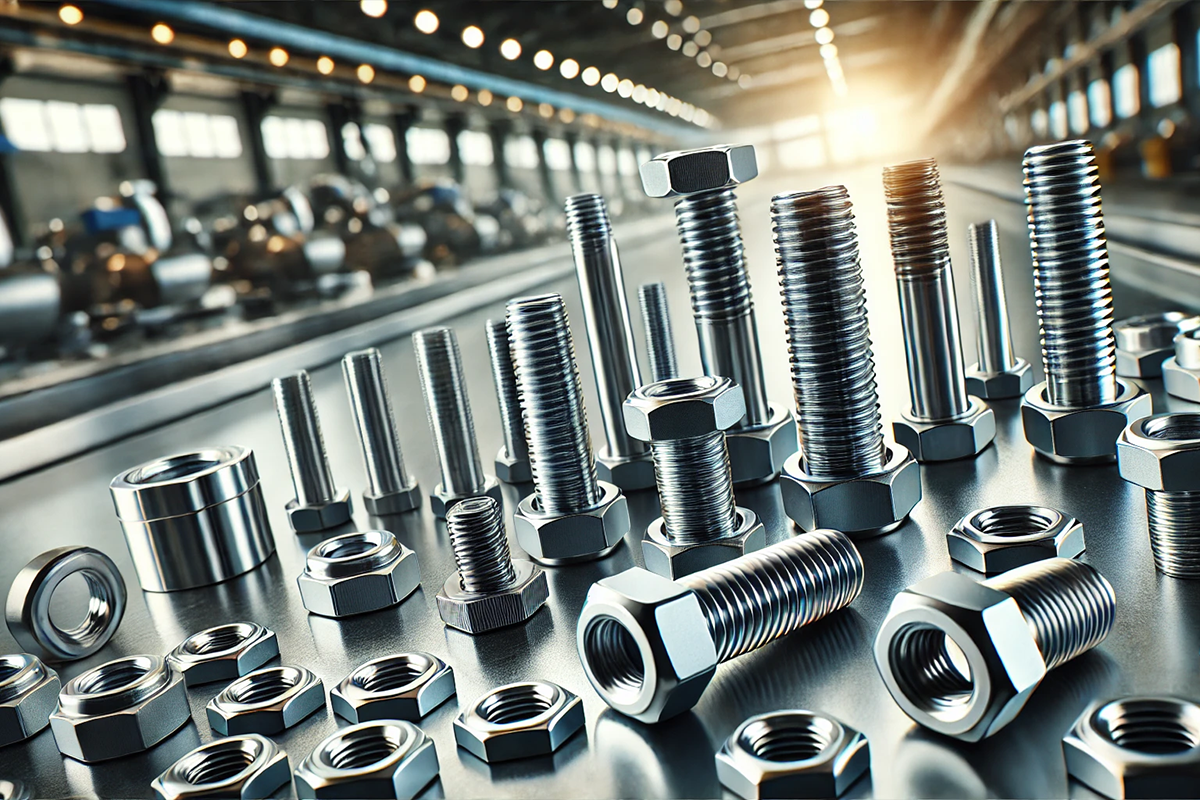

Things to Consider When Buying Bolts in Bulk

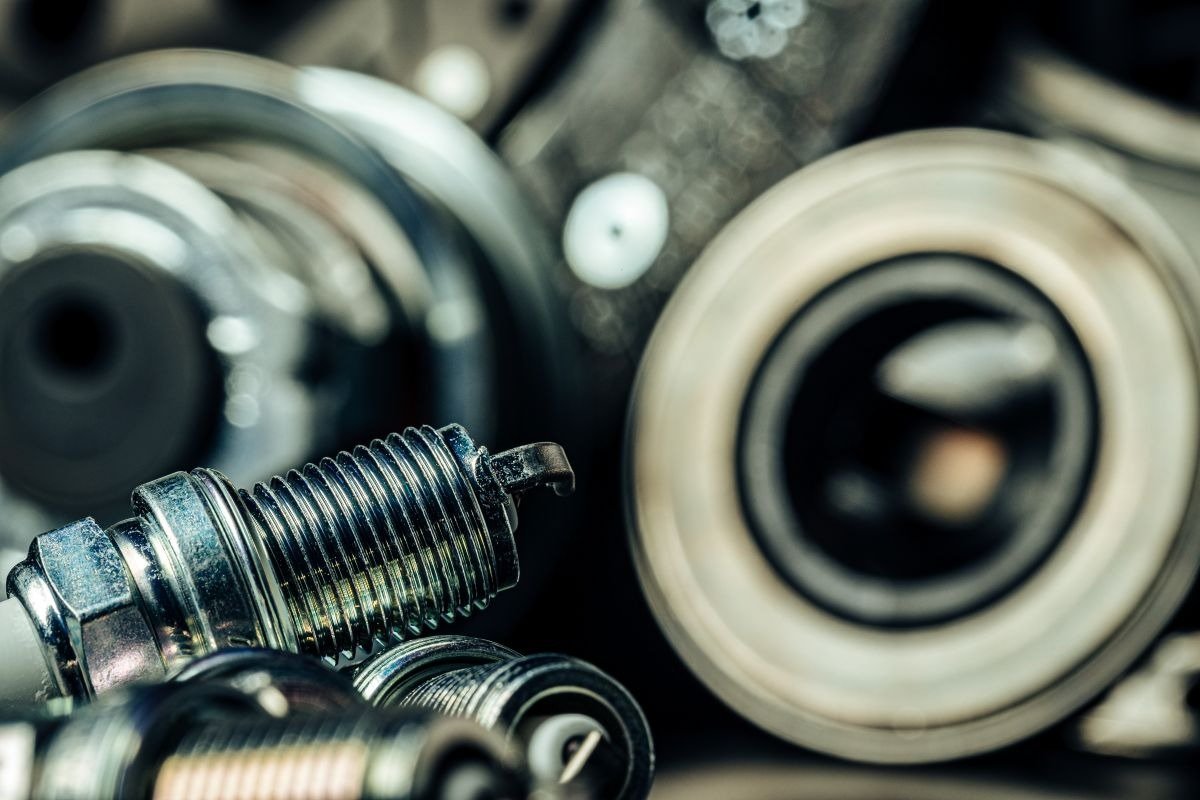

Bolts are the unsung heroes of industry, construction, and

even the automotive sector. These small yet critical components directly impact

the safety and durability of any structure or mechanism. When it comes to bulk

bolt purchasing, especially for large-scale projects or production facilities,

choosing the right product not only provides cost advantages but also ensures

long-term quality and safety. However, this process is not as simple as it may

seem. With hundreds of different types of bolts, each with unique features,

making the right choice requires careful analysis and a solid strategy.

How to Choose Bulk Bolts

Before starting a project, the first step is to determine

the type of bolt to be used. At this point, factors such as the material type,

environmental conditions, and the load to be carried become crucial. If the

bolts will be used outdoors or in humid environments, stainless steel bolts

should be preferred. Otherwise, corrosion over time can reduce the bolt’s

strength and create an undesirable appearance.

Moreover, if your production volume is high or if you have

ongoing needs, buying bolts in bulk will always be a more economical option.

However, beyond choosing the right product, finding a reliable supplier is also

essential. Not every cheap product is of good quality; the quality of raw

materials used in low-priced bolts can cause serious problems down the line.

What to Watch Out for When Buying Bolts in Bulk

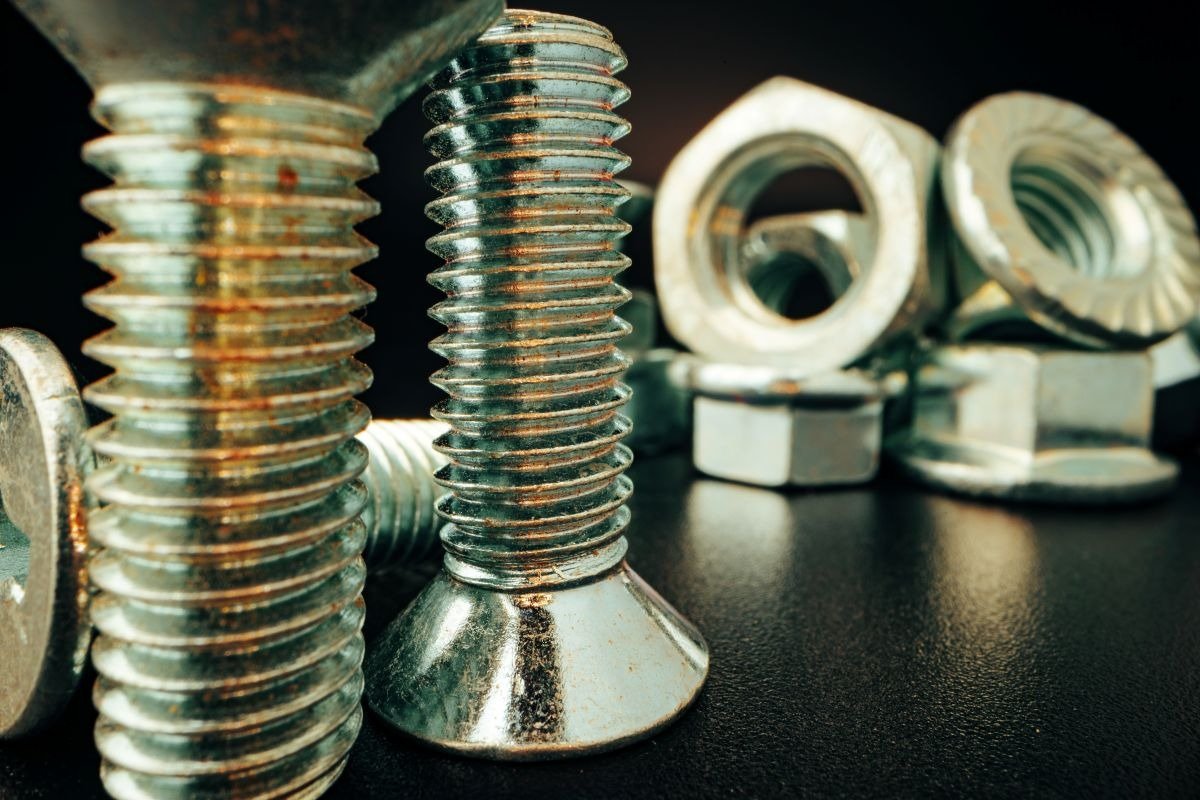

First and foremost, the correct grade and size should be

determined based on the intended application. A bolt used in industrial

manufacturing is not the same as one used for furniture production.

Additionally, before making a purchase, it's important to request technical

documentation from the supplier, including material specs, production

standards, and certifications.

Another critical point is the potential weight variations in

bolt and nut purchases made by weight. Bolts of the same dimensions may

vary in weight depending on the manufacturer, as not all producers use steel of

the same density or quality. This directly affects the Bolt kg price.

You might think you’re getting a good deal, but in reality, you could be

receiving a low-density, and therefore weaker, product. That's why it's

essential to evaluate not just the price, but also the technical details of the

product.

How to Measure Bolt Quality

The key elements that determine a bolt’s quality include

tensile strength, breaking resistance, surface treatment, and material type. A

high-quality bolt is made from high-carbon steel and undergoes a precise heat

treatment process. Additionally, surface coatings enhance the bolt’s

durability. Coatings like galvanization, black oxide, or zinc phosphate provide

strong protection against external elements.

A bolt's quality cannot be assessed by physical appearance

alone. Structural characteristics that aren't visible to the eye but are

critical for performance can only be identified through detailed testing. For

large-volume purchases, always choose tested products with quality

certifications.

Bolt Standards

There are internationally recognized bolt standards. The

most widely used ones are ISO, DIN, and ASTM. Each defines specific dimensions,

tolerances, and strength thresholds. For instance, ISO 898-1 outlines the

mechanical properties of carbon steel bolts. DIN standards, on the other hand,

are based on German measurement systems.

Compliance with standards is not only a legal requirement

but also crucial to prevent issues during assembly. A non-standard bolt may not

fit properly with other parts or machinery, causing loss of time and effort

during installation.

Wholesale Bolt Prices

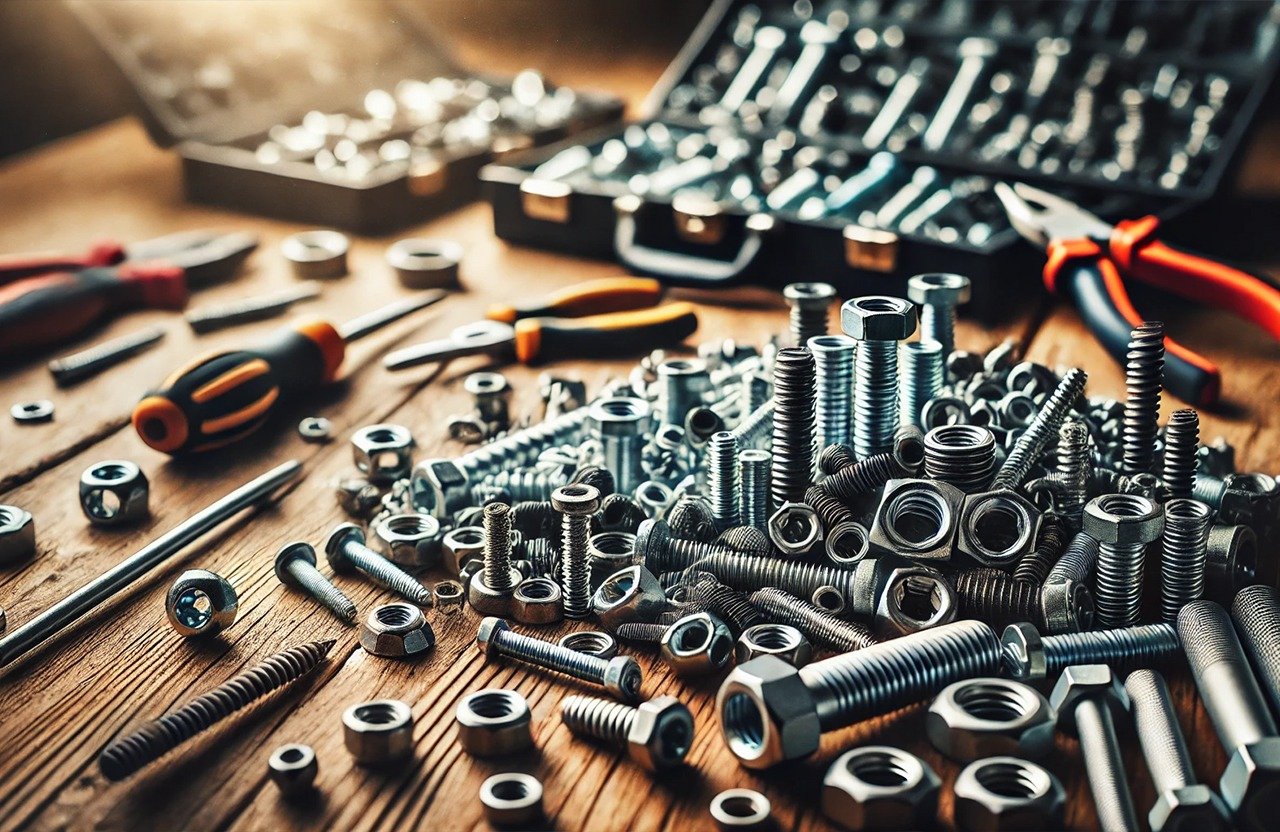

Today, various factors influence bolt prices on the market.

These include raw material prices, exchange rates, production technologies,

quality levels, and supply chain costs. Especially in bulk purchases, wholesale

bolt nut prices are usually evaluated by weight rather than per

piece. Therefore, the Bolt kg price becomes one of the main criteria for

buyers.

How Are Wholesale Bolt Nut Prices Determined?

The most important point to remember is that quality is the

biggest factor in determining price. Choosing a low-priced product may lead to

breakdowns or replacement costs in the future, significantly increasing the

total cost. Therefore, when buying wholesale bolt nut, don’t focus

solely on price—consider the long-term benefits the product will provide.

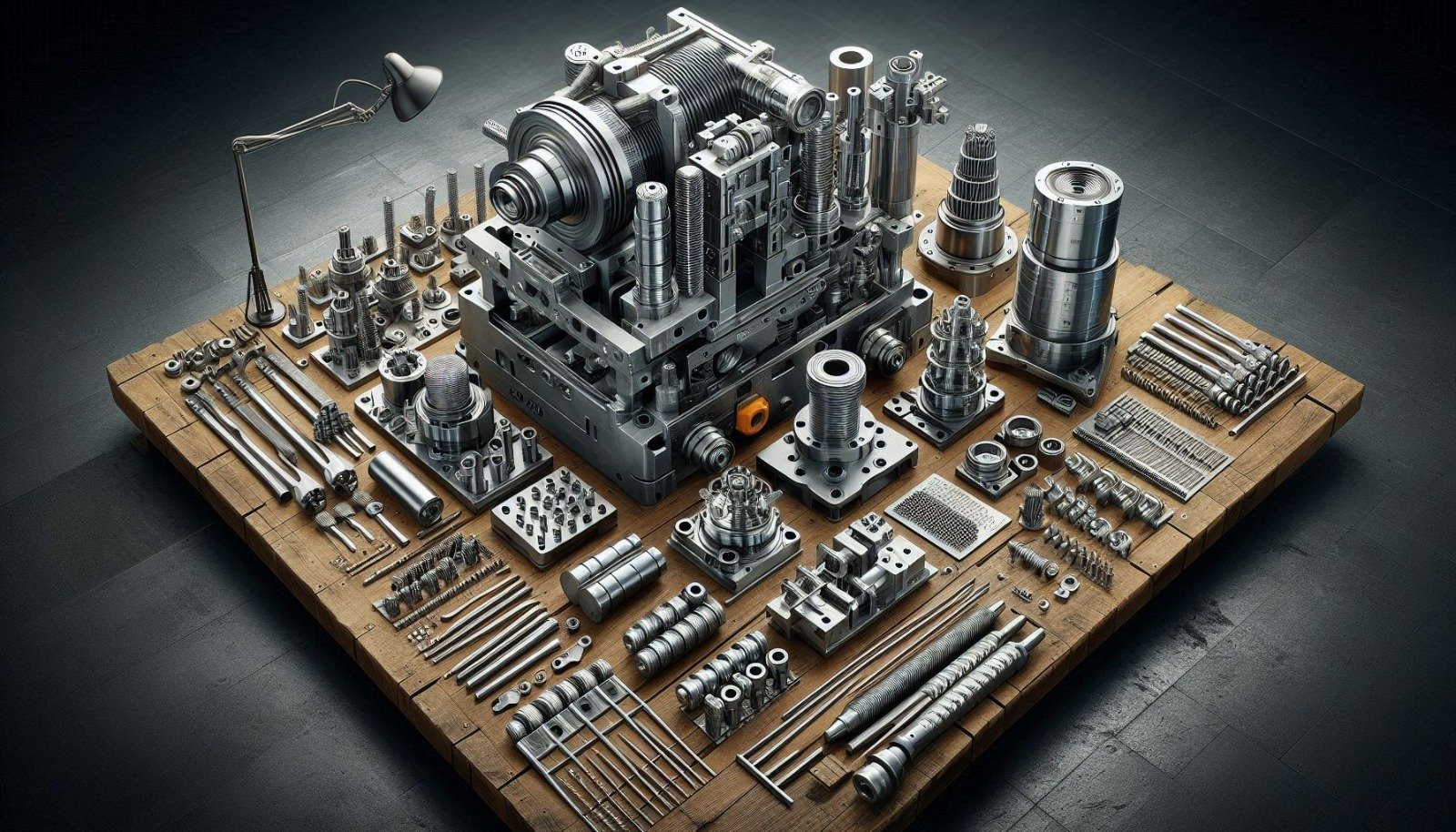

For companies operating in the manufacturing industry,

buying bolts in bulk is a strategic investment. High-quality,

standard-compliant products save time in production, enhance workplace safety,

and minimize potential risks. That’s why working with the right supplier,

analyzing the market well, and making purchasing decisions based on technical

data will always pay off.